1.1mm 2mm 3mm non reflection glass cut to size

Technical data

|

Anti Reflective Glass |

||||||||

|

Thickness |

0.55mm 0.7mm 1.1mm 2mm 3mm 4mm 5mm 6mm |

|||||||

|

Coating type |

one layer one side |

one layer double side |

four layer double side |

multi layer double side |

||||

|

Transmittance |

>92% |

>94% |

>96% |

>98% |

||||

|

Reflectance |

<8% |

<5% |

<3% |

<1% |

||||

|

Functional test |

||||||||

|

Thickness |

steel ball weight(g) |

height(cm) |

||||||

|

Impact test |

0.7mm |

130 |

35 |

|||||

|

1.1mm |

130 |

50 |

||||||

|

2mm |

130 |

60 |

||||||

|

3mm |

270 |

50 |

||||||

|

3.2mm |

270 |

60 |

||||||

|

4mm |

540 |

80 |

||||||

|

5mm |

1040 |

80 |

||||||

|

6mm |

1040 |

100 |

||||||

|

Hardness |

>7H |

|||||||

|

Abrasion test |

0000#steel wool with 1000gf,6000cycles,40cycles/min |

|||||||

|

Reliability test |

||||||||

|

Anti corrsion test(salt spray test) |

NaCL concentration 5%: |

|||||||

|

Humidity resistance test |

60℃,90%RH,48 hours |

|||||||

|

Acid resistance test |

HCL concentration:10%,Temperature: 35°C |

|||||||

|

Alkali resistance test |

NaOH concentration:10%,Temperature: 60°C |

|||||||

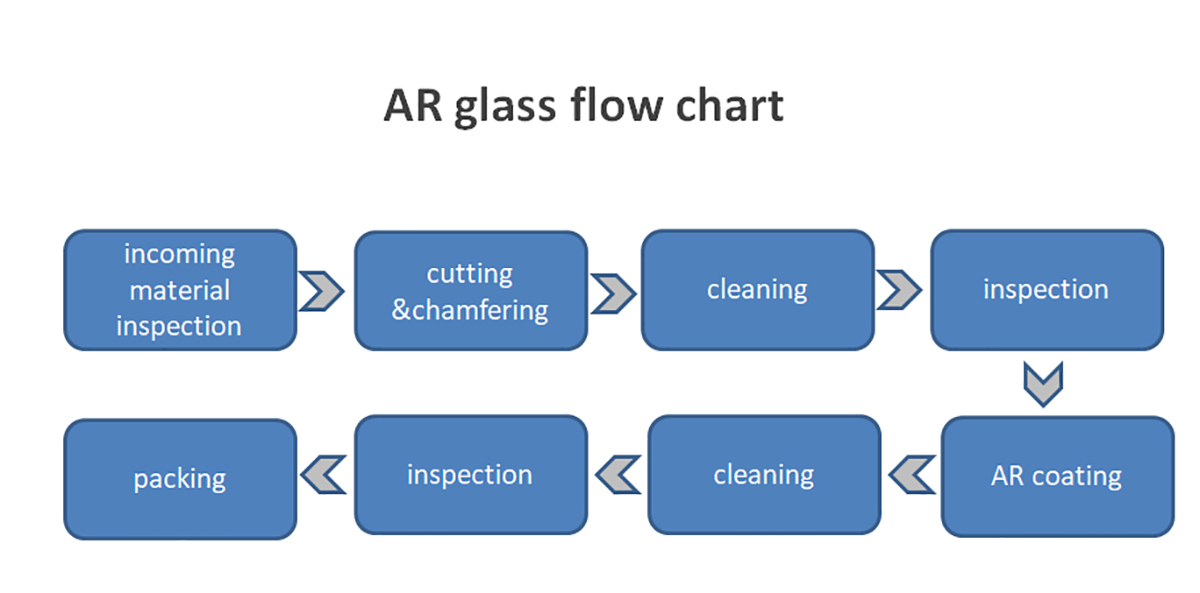

Processing

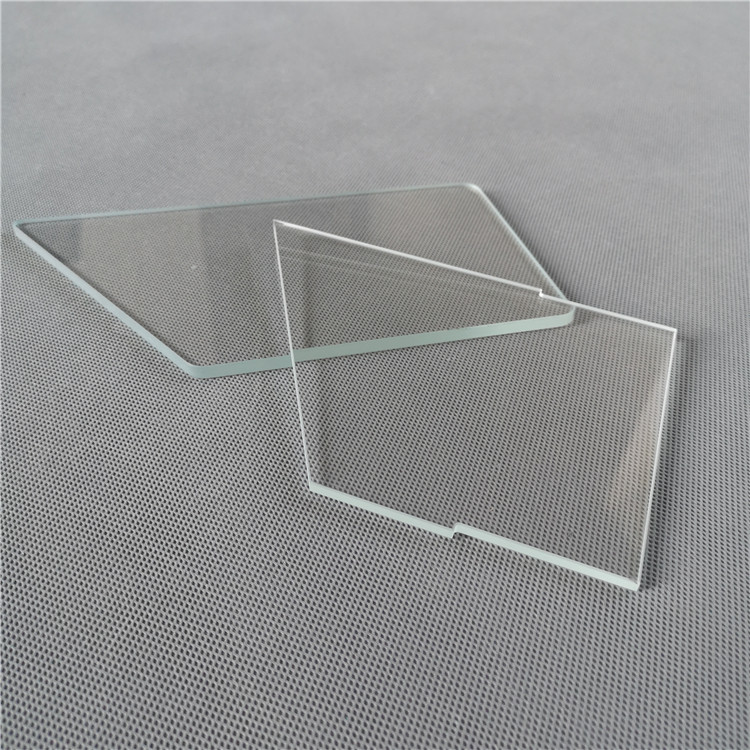

AR glass is also called anti-reflection or anti-reflective glass. It uses the most advanced magnetron sputtering coating technology to coat anti reflective overlay on the surface of ordinary tempered glass, which effectively reduces the reflection of the glass itself and increases the transparency of the glass. The pass rate makes the color originally through the glass more vivid and more real.

1. The highest peak value of visible light transmittance is 99%.

The average transmittance of visible light exceeds 95%, which greatly improves the original brightness of LCD and PDP and reduces energy consumption.

2. The average reflectivity is less than 4%, and the minimum value is less than 0.5%.

Effectively weaken the defect that the screen turns white due to the strong light behind, and enjoy a clearer image quality.

3. Brighter colors and stronger contrast.

Make the image color contrast more intense and the scene clearer.

4. Anti-ultraviolet, effectively protect the eyes.

The transmittance in the ultraviolet spectral region is greatly reduced, which can effectively block the damage of ultraviolet rays to the eyes.

5. High temperature resistance.

AR glass temperature resistance > 500 degrees (generally acrylic can only withstand 80 degrees).

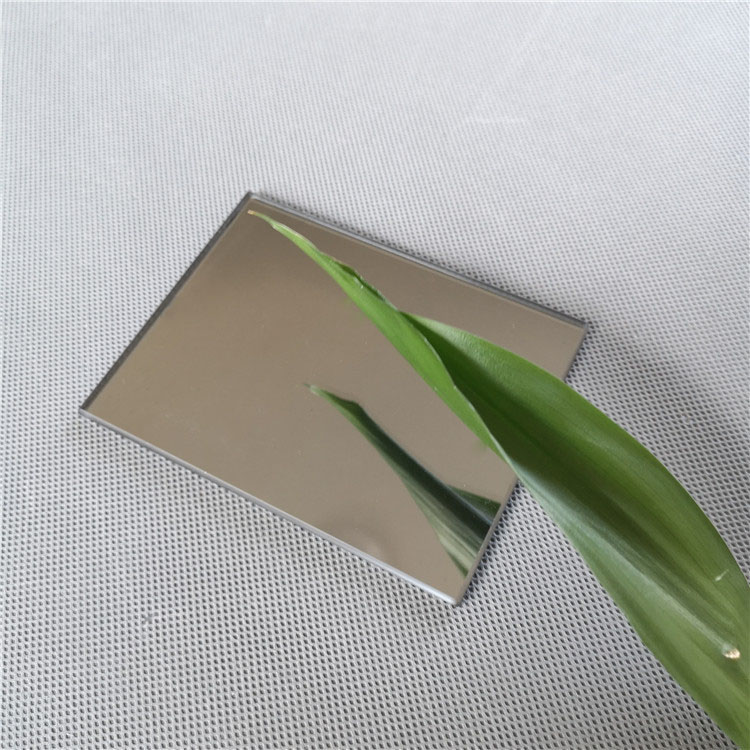

There are coming from different coating type,just for coating color option, will not infect the transmittance.

Yes

For conductive or EMI shielding purpose,we can add ITO or FTO coating.

For anti glare solution,we can adopt anti glare coating together to improving the light reflection control.

For oleophobic solution,anti finger printing coating can be a good combination to improve touch feel and make touch screen easier to clean.

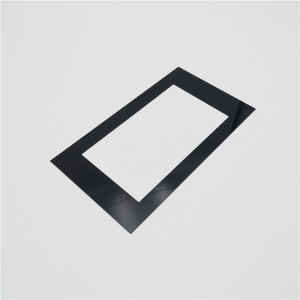

Related application

Ar Coated Glass For Medical Display

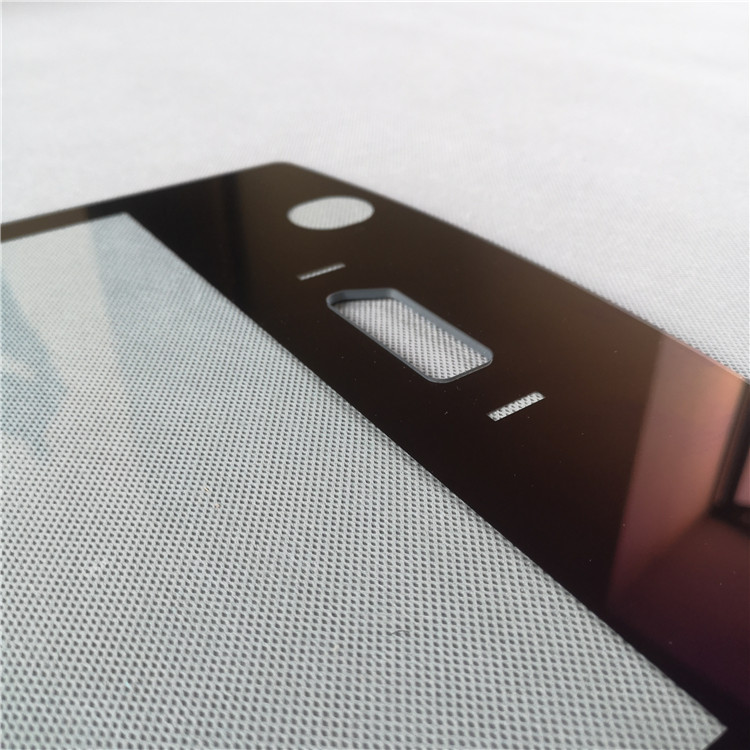

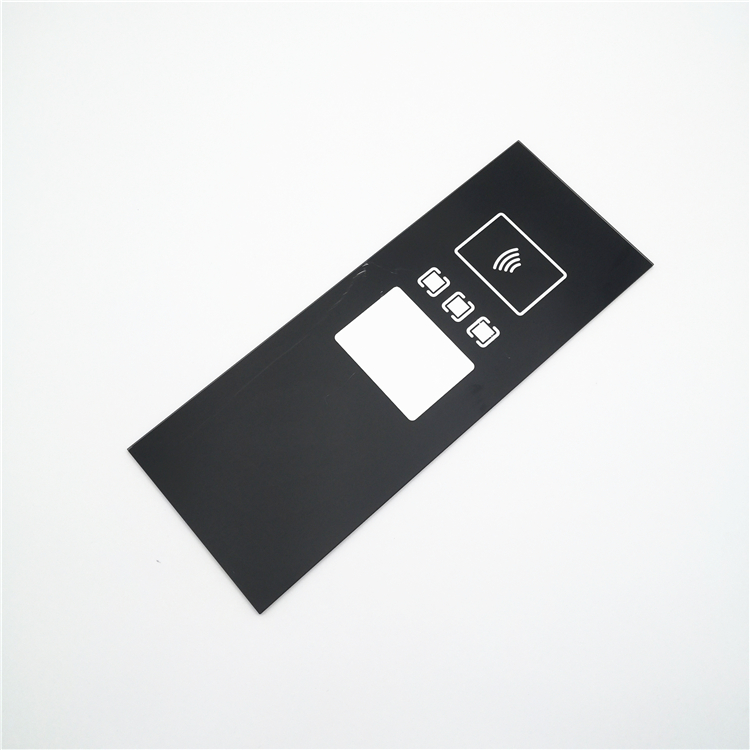

Anti Reflective Tempered Glass For Passport Reader

Anti Reflective Glass For Wayfinding Totem