AG cover glass

Technical data

|

Thickness |

raw material |

spraying coating |

chemical etching |

||||

|

upper |

lower |

upper |

lower |

upper |

lower |

||

|

0.7mm |

0.75 |

0.62 |

0.8 |

0.67 |

0.7 |

0.57 |

|

|

1.1mm |

1.05 |

1.15 |

1.1 |

1.2 |

1 |

1.1 |

|

|

1.5mm |

1.58 |

1.42 |

1.63 |

1.47 |

1.53 |

1.37 |

|

|

2mm |

2.05 |

1.85 |

2.1 |

1.9 |

2 |

1.8 |

|

|

3mm |

3.1 |

2.85 |

3.15 |

2.9 |

3.05 |

2.8 |

|

|

4mm |

4.05 |

3.8 |

4.1 |

3.85 |

4 |

3.75 |

|

|

5mm |

5.05 |

4.8 |

5.1 |

4.85 |

5 |

4.75 |

|

|

6mm |

6.05 |

5.8 |

6.1 |

5.85 |

6 |

5.75 |

|

|

Parameter |

gloss |

roughness |

haze |

transmission |

reflectance |

||

|

35±10 |

0.16±0.02 |

17±2 |

>89% |

~1% |

|||

|

50±10 |

0.13±0.02 |

11±2 |

>89% |

~1% |

|||

|

70±10 |

0.09±0.02 |

6±1 |

>89% |

~1% |

|||

|

90±10 |

0.07±0.01 |

2.5±0.5 |

>89% |

~1% |

|||

|

110±10 |

0.05±0.01 |

1.5±0.5 |

>89% |

~1% |

|||

|

Impact test |

Thickness |

steel ball weight(g) |

height(cm) |

||||

|

0.7mm |

130 |

35 |

|||||

|

1.1mm |

130 |

50 |

|||||

|

1.5mm |

130 |

60 |

|||||

|

2mm |

270 |

50 |

|||||

|

3mm |

540 |

60 |

|||||

|

4mm |

540 |

80 |

|||||

|

5mm |

1040 |

80 |

|||||

|

6mm |

1040 |

100 |

|||||

|

Hardness |

>7H |

||||||

|

|

AG spraying coating |

AG chemical etching |

|||||

|

Anti corrsion test |

NaCL concentration 5%: |

N/A |

|||||

|

Humidity resistance test |

60℃,90%RH,48 hours |

N/A |

|||||

|

Abrasion test |

0000#fsteel wool with 100ogf ,6000cycles,40cycles/min |

N/A |

|||||

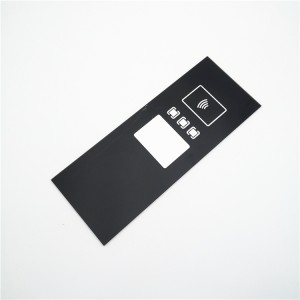

Processing

Anti-glare glass, referred to as AG glass, is a kind of glass with special treatment on the glass surface. The principle is to process high-quality overlay on single or both sides to make it have a lower reflectance than ordinary glass, thereby reducing the interference of ambient light, improving the clarity of the picture, reducing screen reflection, and making the image cleaner and more realistic, allowing viewers to enjoy better visual effects.

The production principle of AG glass is divided into AG physical spray coating and AG chemical etching

1. AG spraying coating glass

It means that by means of pressure or centrifugal force, particles such as sub-micron silica are uniformly coated on the glass surface through a spray gun or a disc atomizer, and after heating and curing treatment, a layer of particles is formed on the glass surface. Diffuse reflection of light to achieve anti-glare effect

As it is spraying a coating on the surface of glass,so glass thickness will be a little thicker after coating.

2. AG chemical etching glass.

It refers to the use of chemical reactions.it requires chemicals such as hydrofluoric acid, hydrochloric acid, and sulfuric acid to etching the glass surface from glossy to matt with micron particle surface, which is the result of the combined action of ionization equilibrium, chemical reaction, dissolution and recrystallization, ion replacement and other reactions.

As it is etching the glass surface,so glass thickness will be a little bit thinner than before.

For conductive or EMI shielding purpose,we can add ITO or FTO coating.

For anti glare solution, we can adopt anti glare coating together to improving the light reflection control.

For oleophobic solution,anti finger printing coating can be best combination to improve touch feel and make touch screen easier to clean.

AG(anti glare) glass VS AR( anti reflective) glass,what is the difference,which one better. read more

Related application

Chemical resistant anti glare glass for industrial touch panel

Large size anti glare glass for digital signage touch screens

Non glare glass cover lens for car navigation touch screen