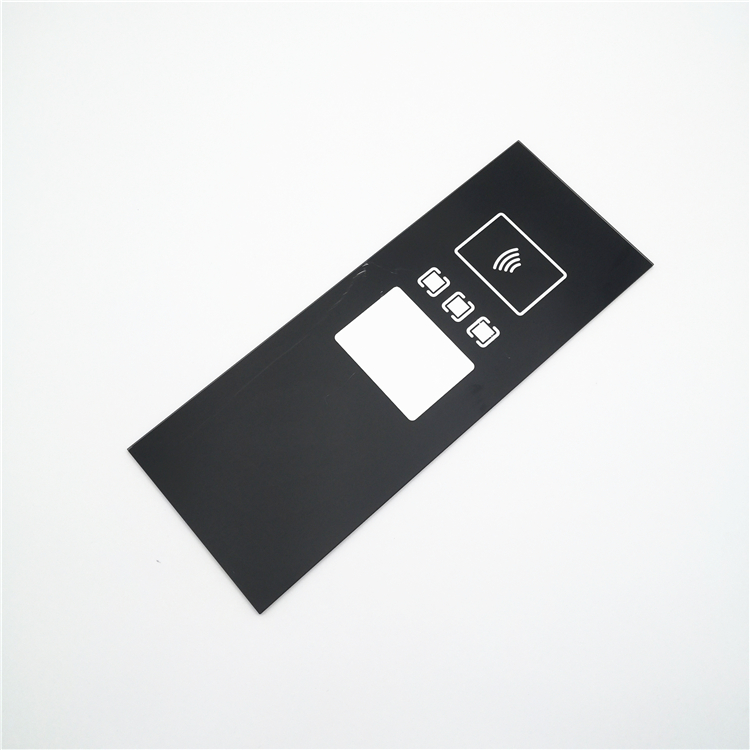

Cover glass,cover lens for optical bonding

Processing

When it comes to optical bonding,it requires lower warpage between cover glass and LCD panel,any unacceptable gap out of tolerance will infect the bonding and whole sensors.

Chemically strengthened can control the glass warpage <0.2mm(take 3mm for example).

While thermally tempered only can be <0.5mm (take 3mm for example).

Central stress :450Mpa-650Mpa,which makes glass have better performance in scratch resistant.

Technical Data

|

Aluminosilicate glass |

Soda lime glass |

|||||

|

Type |

corning gorilla glass |

dragontrail glass |

Schott Xensat |

panda glass |

NEG T2X-1 glass |

float glass |

|

Thickness |

0.4mm,0.5mm,0.55mm,0.7mm 1mm,1.1mm,1.5mm,2mm |

0.55mm,0.7mm,0.8mm 1.0mm,1.1mm,2.0mm |

0.55mm,0.7mm 1.1mm |

0.7mm,1.1mm |

0.55mm,0.7mm 1.1mm |

0.55mm,0.7mm,1.1mm,2mm 3mm,4mm,5mm,6mm |

|

Chemical strengthened |

DOL≥ 40um CS≥700Mpa |

DOL≥ 35um CS≥650Mpa |

DOL≥ 35um CS≥650Mpa |

DOL≥ 32um CS≥600Mpa |

DOL≥ 35um CS≥650Mpa |

DOL≥ 8um CS≥450Mpa |

|

Hardness |

≥9H |

≥9H |

≥7H |

≥7H |

≥7H |

≥7H |

|

Transmittance |

>92% |

>90% |

>90% |

>90% |

>90% |

>89% |

Flow chart

Quality Control

Our packing