custom 2mm fto conductive glass

Technical data

|

ITO glass thickness |

0.4mm,0.5mm,0.55mm,0.7mm,1mm,1.1mm,2mm,3mm,4mm |

||||||||

|

resistance |

3-5Ω |

7-10Ω |

12-18Ω |

20-30Ω |

30-50Ω |

50-80Ω |

60-120Ω |

100-200Ω |

200-500Ω |

|

coating thickness |

2000-2200Å |

1600-1700Å |

1200-1300Å |

650-750Å |

350-450Å |

200-300Å |

150-250Å |

100-150Å |

30-100Å |

|

Glass resistance |

|||

|

Resistance type |

low resistance |

normal resistance |

high resistance |

|

Definition |

<60Ω |

60-150Ω |

150-500Ω |

|

Application |

High resistance glass is generally used for electrostatic protection and touch screen production |

Ordinary resistance glass is generally used for TN type liquid crystal display and electronic anti-interference(EMI shielding) |

Low resistance glass is generally used in STN liquid crystal displays and transparent circuit boards |

|

Functional test and reliability test |

|

|

Tolerance |

±0.2mm |

|

Warpage |

thickness <0.55mm,warpage≤0.15% thickness>0.7mm,warpage≤0.15% |

|

Z-T vertical |

≤1° |

|

Hardness |

>7H |

|

Coating Abrasion test |

0000#steel wool with 1000gf,6000cycles,40cycles/min |

|

Anti corrsion test(salt spray test) |

NaCL concentration 5%: Temperature: 35°C Experiment time: 5min resistance change≤10% |

|

Humidity resistance test |

60℃,90%RH,48 hours resistance change≤10% |

|

Acid resistance test |

HCL concentration:6%,Temperature: 35°C Experiment time: 5min resistance change≤10% |

|

Alkali resistance test |

NaOH concentration:10%,Temperature: 60°C Experiment time: 5min resistance change≤10% |

|

Themal stability |

Temperature:300°C heating time:30min resistance change≤300% |

Processing

Si02 layer:

(1) The role of the SiO2 layer:

The main purpose is to prevent the metal ions in the soda-calcium substrate from diffusing into the ITO layer. It affects the conductivity of the ITO layer.

(2) Film thickness of SiO2 layer:

The standard film thickness is generally 250 ± 50 Å

(3) Other components in the SiO2 layer:

Usually, in order to improve the transmittance of ITO glass, a certain proportion of SiN4 is doped into SiO2.

| GLASS RESISTANCE | ||||||

| TYPE | low resistance | normal resistance | high resistance | |||

| Definition | <60Ω | 60-150Ω | 150-500Ω | |||

| Application | High resistance glass is generally used for electrostatic protection and touch screen production | Ordinary resistance glass is generally used for TN type liquid crystal display and electronic anti-interference(EMI shielding) | Low resistance glass is generally used in STN liquid crystal displays and transparent circuit boards | |||

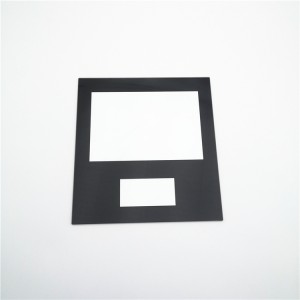

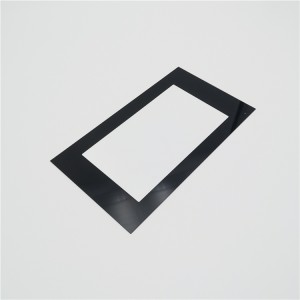

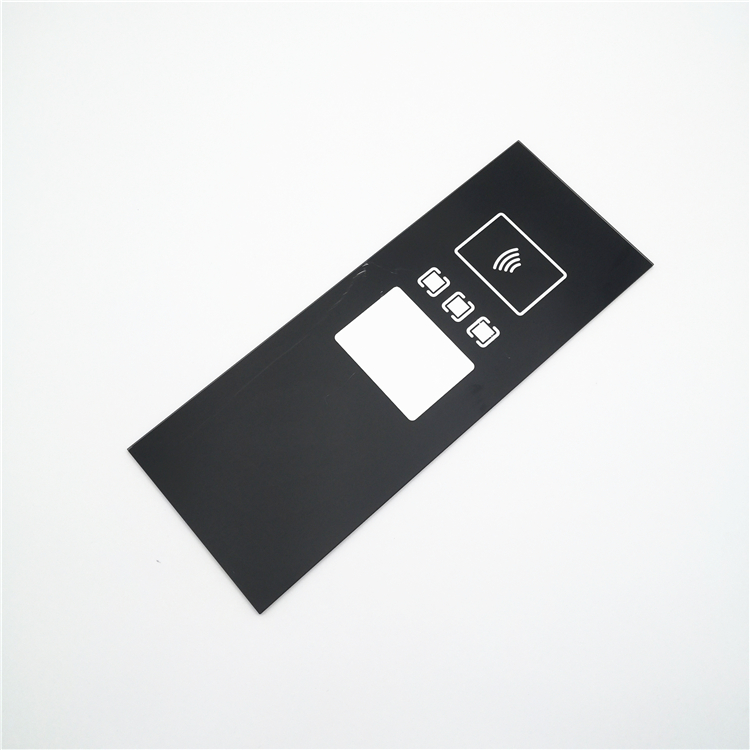

Related application

Ito Glass For Military Emi Shielding Display

Ito Coated Glass For Hmi Touch Panel

Tempered Ito Conductive Glass For Body Scale