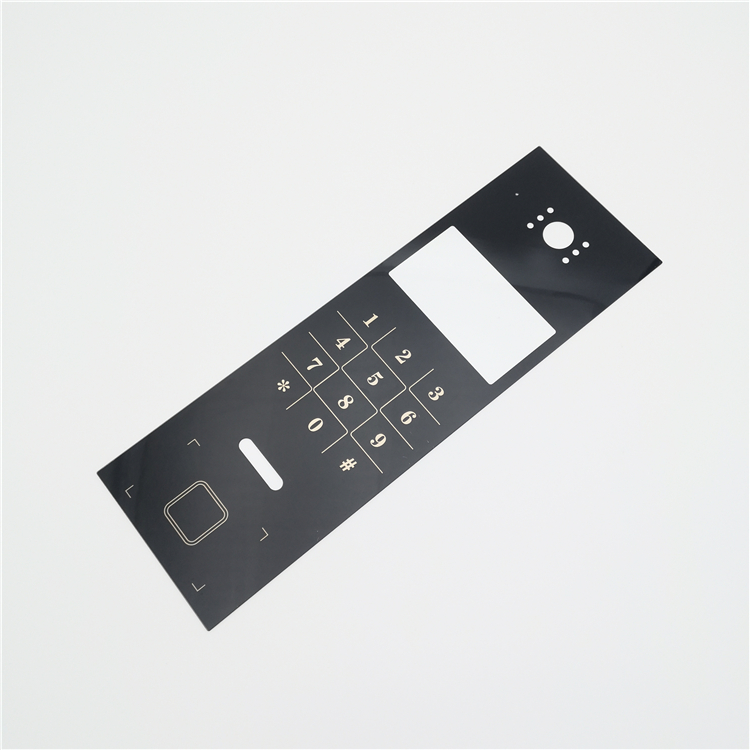

1.1mm 2mm low gilashin nuni |gilashin da anti-glare shafi

Bayanan fasaha

| Kauri | albarkatun kasa | spraying shafi | sinadaran etching | ||||

| babba | kasa | babba | kasa | babba | kasa | ||

| 0.7mm ku | 0.75 | 0.62 | 0.8 | 0.67 | 0.7 | 0.57 | |

| 1.1mm | 1.05 | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5mm | 1.58 | 1.42 | 1.63 | 1.47 | 1.53 | 1.37 | |

| 2mm ku | 2.05 | 1.85 | 2.1 | 1.9 | 2 | 1.8 | |

| 3 mm | 3.1 | 2.85 | 3.15 | 2.9 | 3.05 | 2.8 | |

| 4mm ku | 4.05 | 3.8 | 4.1 | 3.85 | 4 | 3.75 | |

| 5mm ku | 5.05 | 4.8 | 5.1 | 4.85 | 5 | 4.75 | |

| 6mm ku | 6.05 | 5.8 | 6.1 | 5.85 | 6 | 5.75 | |

| Siga | sheki | m | hazo | watsawa | tunani | ||

| 35± 10 | 0.16 ± 0.02 | 17±2 | > 89% | ~1% | |||

| 50± 10 | 0.13 ± 0.02 | 11 ± 2 | > 89% | ~1% | |||

| 70± 10 | 0.09± 0.02 | 6±1 | > 89% | ~1% | |||

| 90± 10 | 0.07± 0.01 | 2.5 ± 0.5 | > 89% | ~1% | |||

| 110± 10 | 0.05± 0.01 | 1.5 ± 0.5 | > 89% | ~1% | |||

| Gwajin tasiri | Kauri | karfe ball nauyi(g) | tsawo (cm) | ||||

| 0.7mm ku | 130 | 35 | |||||

| 1.1mm | 130 | 50 | |||||

| 1.5mm | 130 | 60 | |||||

| 2mm ku | 270 | 50 | |||||

| 3 mm | 540 | 60 | |||||

| 4mm ku | 540 | 80 | |||||

| 5mm ku | 1040 | 80 | |||||

| 6mm ku | 1040 | 100 | |||||

| Tauri | >7H | ||||||

|

| AG spraying shafi | Abubuwan da aka bayar na AG Chemical | |||||

| Gwajin rigakafin lalata | NaCL maida hankali 5%: | N/A | |||||

| Gwajin juriya na danshi | 60 ℃, 90% RH, 48 hours | N/A | |||||

| Gwajin abrasion | 0000 # ulu mai ulu tare da 100ogf ,6000cycles, 40cycles/min | N/A | |||||

Gudanarwa

Gilashin anti-glare, wanda ake magana da shi azaman gilashin AG, wani nau'in gilashi ne tare da jiyya na musamman akan farfajiyar gilashin.Ka'idar ita ce aiwatar da rufi mai inganci a kan guda ɗaya ko bangarorin biyu don sanya shi yana da ƙaramin haske fiye da gilashin na yau da kullun, don haka rage tsangwama na hasken yanayi, inganta tsabtar hoton, rage tunanin allo, da sanya hoton ya zama mai tsabta mafi haƙiƙa, kyale masu kallo su ji daɗin ingantattun tasirin gani.

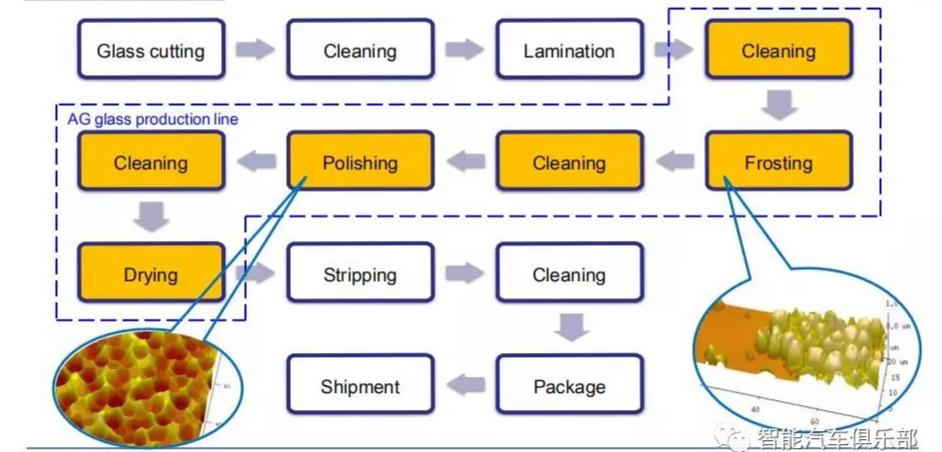

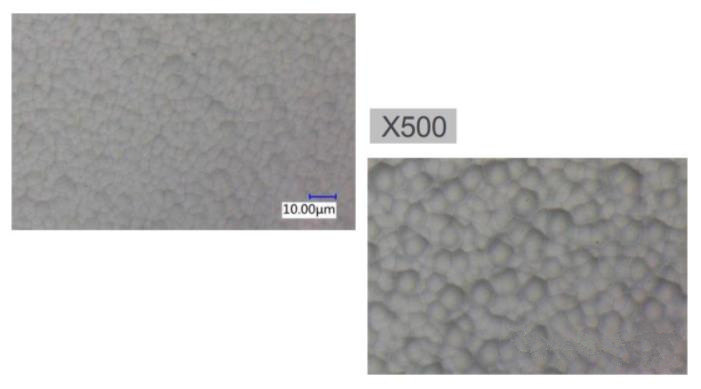

Ka'idar samar da gilashin AG ta kasu kashi-kashi na feshi ta jiki da AG sinadaran etching

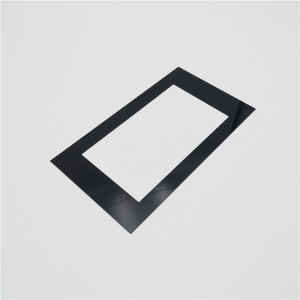

1. AG spraying shafi gilashin

Yana nufin cewa ta hanyar matsi ko centrifugal ƙarfi, barbashi irin su sub-micron silica suna lulluɓe iri ɗaya a saman gilashin ta hanyar bindigar feshi ko atomizer na diski, sannan bayan dumama da warkarwa, an sami wani yanki na barbashi akan gilashin. farfajiya.Yada haske na haske don cimma sakamako mai kyalli

Kamar yadda yake fesa wani shafi a saman gilashin, don haka kaurin gilashin zai yi ɗan kauri bayan an rufe shi.

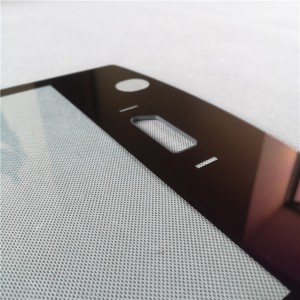

2. AG sinadaran etching gilashin.

Yana nufin yin amfani da sinadaran halayen.yana buƙatar sinadarai irin su hydrofluoric acid, hydrochloric acid, da sulfuric acid zuwa etching da gilashin surface daga m zuwa matt tare da micron barbashi surface, wanda shi ne sakamakon hade mataki na ionization ma'auni, sunadarai. dauki, rushewa da recrystallization, maye gurbin ion da sauran halayen.

Yayin da yake etching saman gilashin, don haka kaurin gilashin zai yi ɗan ƙaranci fiye da da.

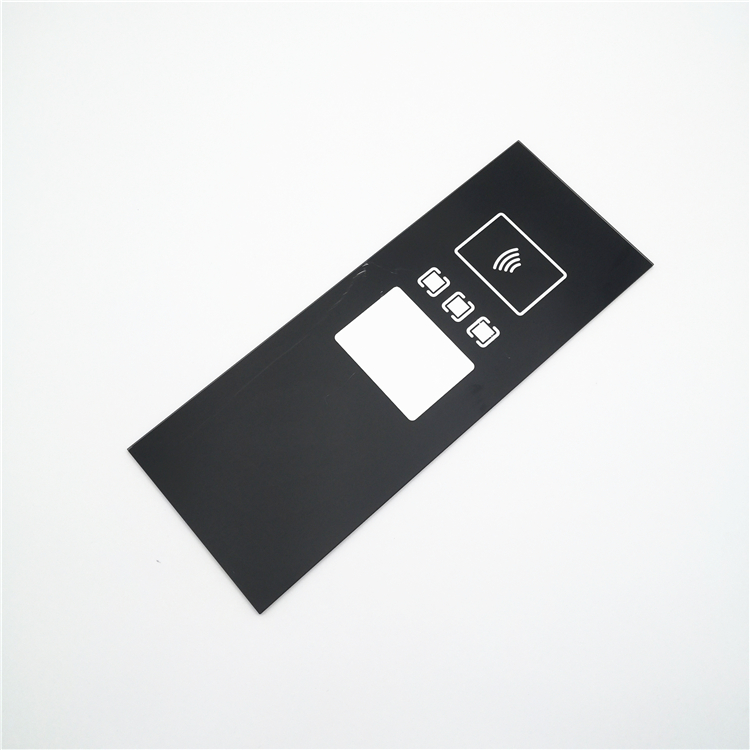

Domin gudanar da ko EMI garkuwa manufa, za mu iya ƙara ITO ko FTO shafi.

Don maganin glare, za mu iya ɗaukar murfin anti glare tare don haɓaka ikon sarrafa haske.

Domin oleophobic bayani, anti yatsa bugu shafi na iya zamamafi kyauhaɗe don haɓaka jin taɓawa da sauƙaƙe allon taɓawa don tsaftacewa.

AG (anti glare) gilashin VS AR (anti mai haske) gilashin, menene bambanci, wanda mafi kyau.kara karantawa

Aikace-aikace masu alaƙa

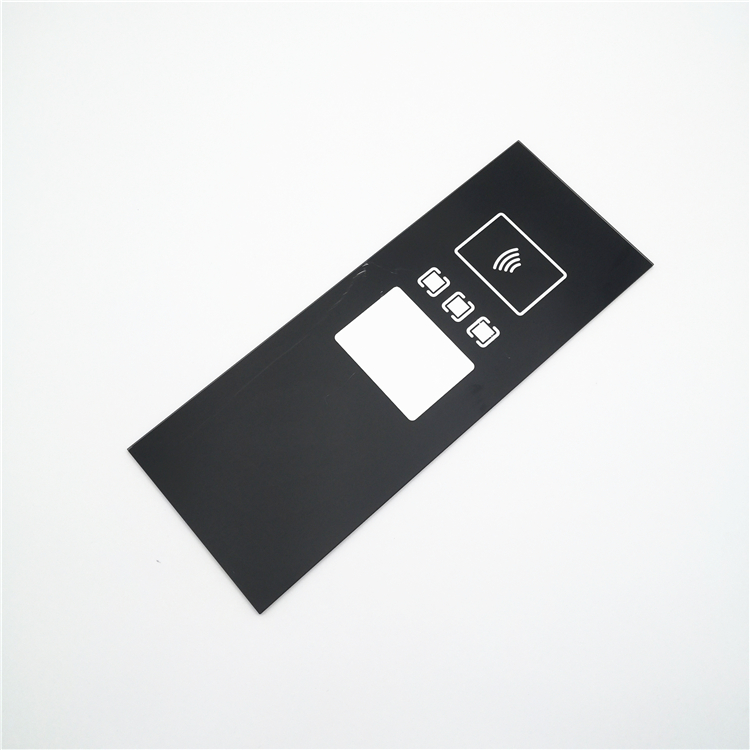

Chemical resistant anti glare gilashin ga masana'antu taba panel

Babban girman gilashin anti glare don alamun taɓawa na dijital

Ruwan tabarau mara kyalli na murfin gilashi don allon taɓawa na mota