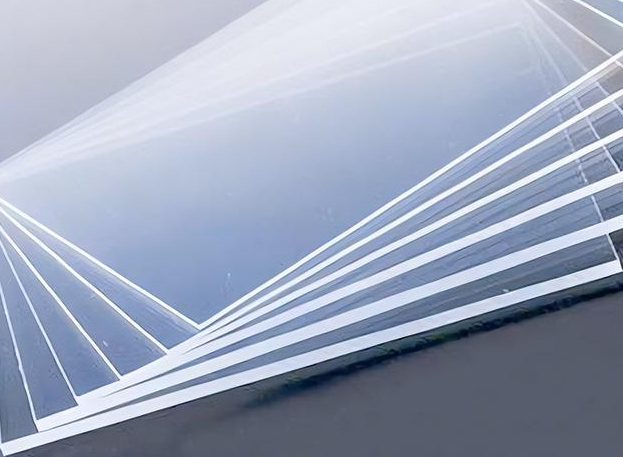

FTO (Fluorine-doped Tin Oxide) gilashin da ITO (Indium Tin Oxide) gilashin duka nau'ikan gilashin ne, amma sun bambanta ta fuskar matakai, aikace-aikace, da kaddarorin.

Ma'ana da Abun Haɗi:

ITO Conductive Glass shine gilashin da ke da sikirin fim ɗin indium tin oxide wanda aka ajiye akan gilashin soda-lemun tsami ko gilashin tushen silicon-boron ta amfani da hanya kamar magnetron sputtering.

FTO Conductive Glass yana nufin gilashin gudanarwar tin dioxide wanda aka yi da fluorine.

Abubuwan Gudanarwa:

Gilashin ITO yana nuna kyakkyawan aiki idan aka kwatanta da gilashin FTO.Wannan haɓakar haɓakar haɓakawa yana haifar da shigar da indium ions cikin tin oxide.

Gilashin FTO, ba tare da magani na musamman ba, yana da babban shinge mai yuwuwar shinge-Layer kuma ba shi da inganci wajen watsa wutar lantarki.Wannan yana nufin cewa gilashin FTO yana da ƙarancin ƙarancin aiki.

Farashin masana'anta:

Farashin masana'anta na gilashin FTO yana da ƙasa kaɗan, kusan kashi ɗaya bisa uku na farashin gilashin sarrafa ITO.Wannan ya sa gilashin FTO ya zama mafi gasa a wasu fannoni.

Sauƙaƙe:

Tsarin etching don gilashin FTO yana da sauƙi idan aka kwatanta da gilashin ITO.Wannan yana nufin cewa gilashin FTO yana da ingantaccen aiki mafi girma.

Juriya Mai Girma:

Gilashin FTO yana nuna mafi kyawun juriya ga yanayin zafi fiye da ITO kuma yana iya jure yanayin zafi har zuwa digiri 700.Wannan yana nuna cewa gilashin FTO yana ba da kwanciyar hankali a cikin yanayin zafi mai zafi.

Resistance Sheet da Watsawa:

Bayan sintering, FTO gilashin yana nuna ƙananan canje-canje a cikin juriya na takarda kuma yana ba da sakamako mafi kyau don buga lantarki idan aka kwatanta da gilashin ITO.Wannan yana nuna cewa gilashin FTO yana da daidaito mafi kyau yayin masana'anta.

Gilashin FTO yana da mafi girman juriya na takarda da ƙananan watsawa.Wannan yana nufin cewa gilashin FTO yana da ƙananan watsa haske.

Iyakar aikace-aikace:

Gilashin sarrafa ITO ana amfani da shi sosai don kera fina-finai masu ɗaukar hoto, gilashin kariya, da makamantansu.Yana ba da tasirin kariya da ya dace da mafi kyawun watsa haske idan aka kwatanta da gilashin garkuwar kayan grid na al'ada.Wannan yana nuna cewa gilashin sarrafa ITO yana da fa'idar aikace-aikace a wasu wurare.

Hakanan za'a iya amfani da gilashin sarrafa FTO don samar da fina-finai masu gudana a bayyane, amma iyakokin aikace-aikacen sa sun fi kunkuntar.Wannan na iya kasancewa saboda ƙarancin ƙarfin aiki da watsawa.

A taƙaice, gilashin sarrafawa na ITO ya zarce gilashin gudanarwa na FTO dangane da aiki, juriya mai zafi, da iyakokin aikace-aikace.Koyaya, gilashin sarrafa FTO yana da fa'ida a cikin farashin masana'anta da sauƙin etching.Zaɓin tsakanin waɗannan gilashin ya dogara da takamaiman buƙatun aikace-aikacen da la'akari da farashi.