2 hli tempered iav

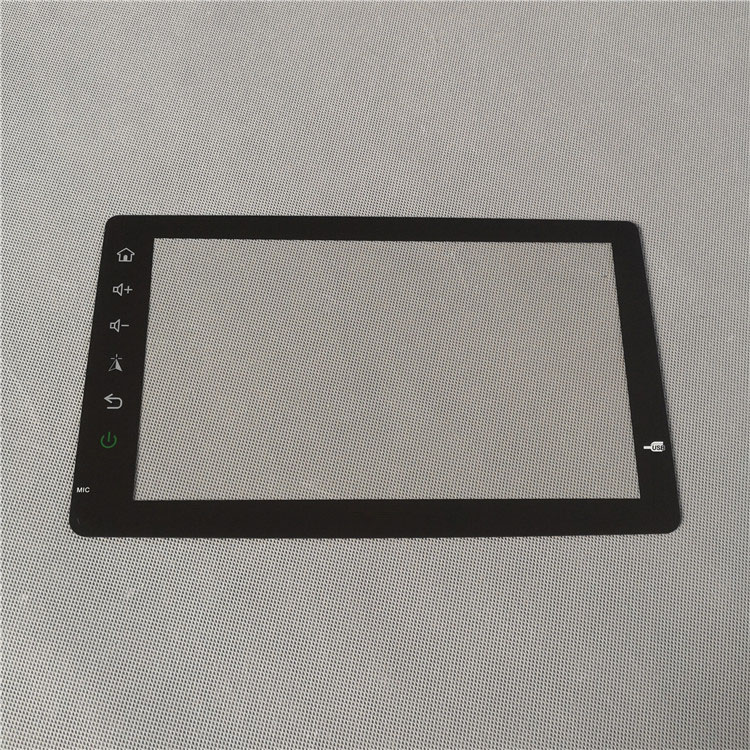

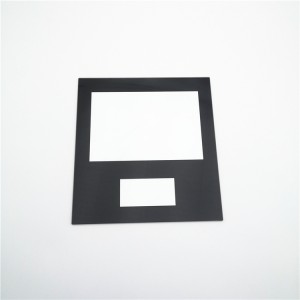

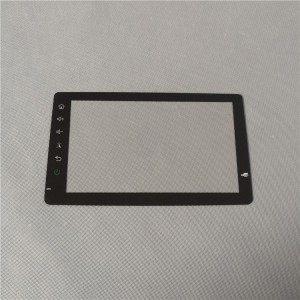

Cov khoom Pics

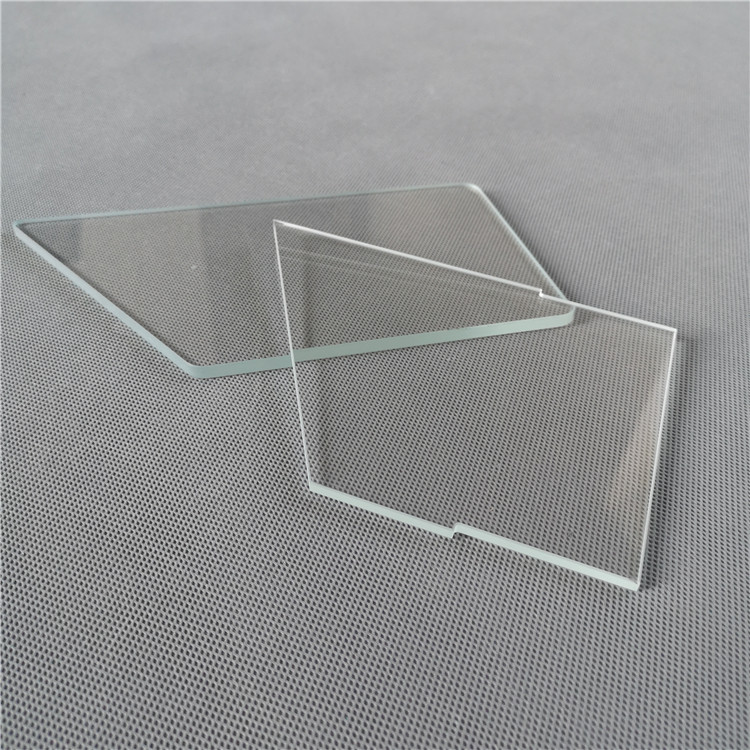

ITO conductive coated iav yog tsim los ntawm kev sib kis ntawm silicon dioxide (SiO2) thiab indium tin oxide (feem ntau hu ua ITO) txheej los ntawm magnetron sputtering technology ntawm iav substrate nyob rau hauv tag nrho vacuumed mob, ua coated lub ntsej muag conductive, ITO yog ib tug hlau compound nrog zoo pob tshab thiab conductive zog.

Cov ntaub ntawv technical

| ITO iav thickness | 0.4 hli, 0.5 hli, 0.55 hli, 0.7 hli, 1 hli, 1.1 hli, 2 hli, 3 hli, 4 hli | ||||||||

| tsis kam | 3-5Ω | 7-10Ω | 12-18Ω | 20-30Ω | 30-50Ω | 50-80Ω | 60-120Ω | 100-200Ω | 200-500Ω |

| txheej thickness | 2000-2200 Nws | 1600-1700 Nws | 1200-1300 Nws | 650-750 Ib | 350-450 Ib | 200-300 Nws | 150-250 Nws | 100-150 Ib | 30-100 Nws |

| iav tsis kam | |||

| Hom kev tiv thaiv | tsis muaj zog | ib txwm tsis kam | siab tsis kam |

| Txhais | <60Ω | 60-150Ω | 150-500Ω |

| Daim ntawv thov | Cov iav ua haujlwm siab feem ntau yog siv rau kev tiv thaiv electrostatic thiab kov npo ntau lawm | Ordinary kuj iav feem ntau yog siv rau TN hom kua siv lead ua zaub thiab hluav taws xob tiv thaiv kev cuam tshuam (EMI shielding) | Cov iav tsis tshua muaj siab yog feem ntau siv hauv STN kua siv lead ua cov lus qhia thiab pob tshab hauv pawg thawj coj saib |

| Kev xeem ua haujlwm thiab kev ntsuas kev ntseeg siab | |

| Ua siab ntev | ± 0.2 hli |

| Warpage | tuab<0.55mm, warpage≤0.15% thickness>0.7 hli, warpage≤0.15% |

| ZT ntsug | ≤1° |

| Hardness | > 7 H |

| Coating Abrasion Test | 0000 # steel wool nrog 1000gf,6000cycles, 40cycles / min |

| Anti corrsion test (kev kuaj ntsev tsuag) | NaCL concentration 5%:Kub: 35 ° CLub sij hawm sim: 5min kuj hloov ≤10% |

| Humidity resistance test | 60℃,90% RH,48 teev tsis kam hloov ≤10% |

| Acid resistance test | HCL concentration: 6%, Kub: 35 ° CLub sij hawm sim: 5min kuj hloov ≤10% |

| Alkali resistance test | NaOH concentration: 10%, Kub: 60 ° CLub sij hawm sim: 5min kuj hloov ≤10% |

| Kev ruaj ntseg | Kub: 300 ° CLub sij hawm cua sov: 30min kuj hloov ≤300% |

Daim ntawv thov cuam tshuam

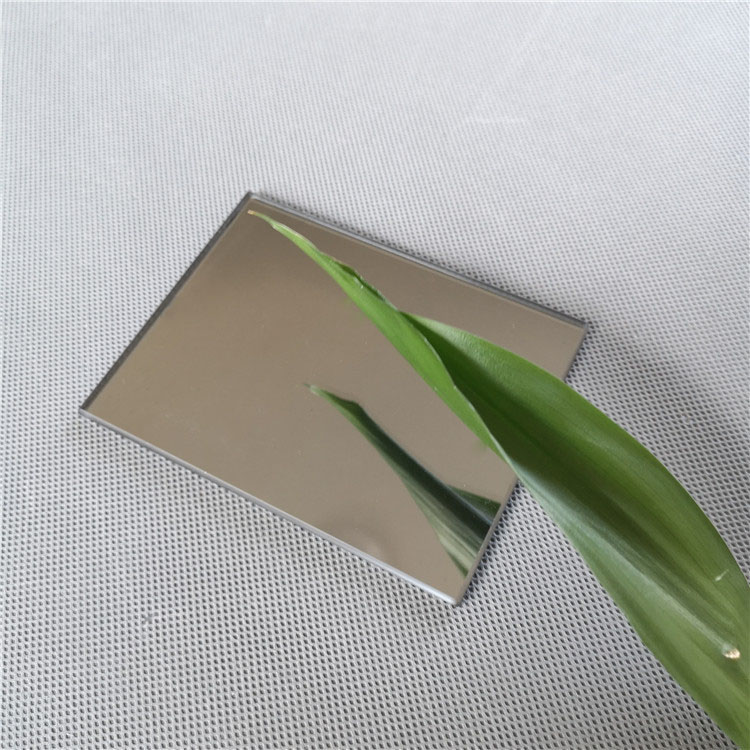

Ito iav Rau Tub Rog Emi Shielding zaub

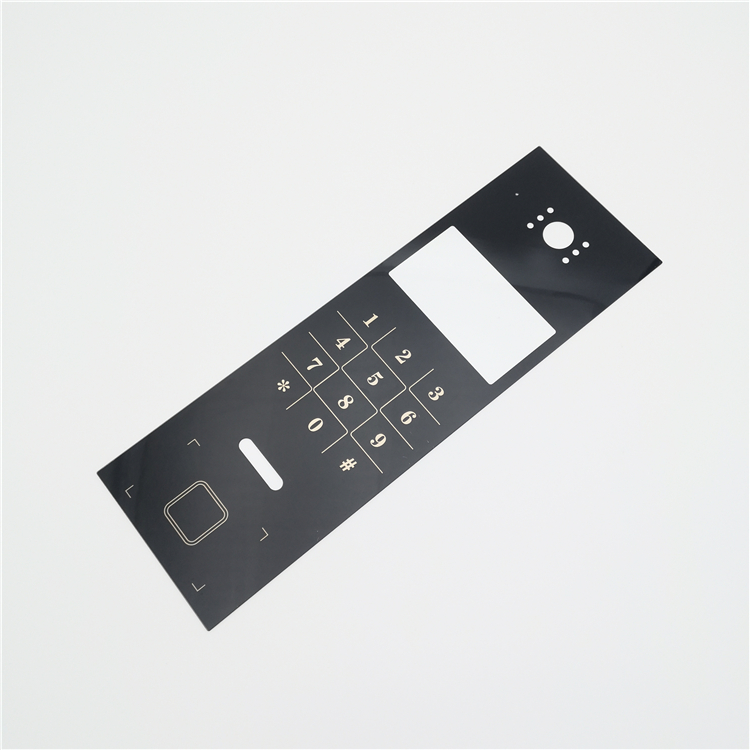

Ito Coated iav Rau Hmi Kov Vaj Huam Sib Luag

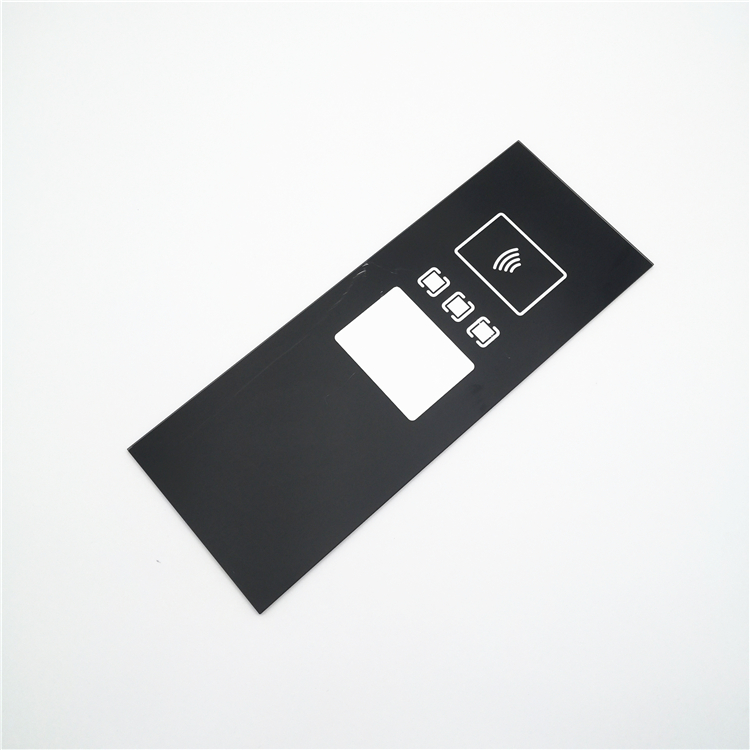

Tempered Ito Conductive iav rau lub cev nplai