anti glare npog iav rau industrial kov saib

Cov ntaub ntawv technical

| Thickness | raw khoom | tshuaj tsuag txheej | tshuaj etching | ||||

| sab sauv | qis | sab sauv | qis | sab sauv | qis | ||

| 0.7mm ib | 0.75 ib | 0.62 ib | 0.8 ua | 0.67 ib | 0.7 ua | 0.57 ib | |

| 1.1 hli | 1.05 Nws | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5 hli | 1.58 ib | 1.42 ib | 1.63 ib | 1.47 ib | 1.53 ib | 1.37 ib | |

| 2 hli | 2.05 Nws | 1.85 ib | 2.1 | 1.9 | 2 | 1.8 | |

| 3mm ib | 3.1 | 2.85 ib | 3.15 | 2.9 | 3.05 Nws | 2.8 | |

| 4mm ib | 4.05 Nws | 3.8 | 4.1 | 3.85 ib | 4 | 3.75 ib | |

| 5mm ib | 5.05 Nws | 4.8 | 5.1 | 4.85 ib | 5 | 4.75 ib | |

| 6mm ib | 6.05 Nws | 5.8 | 6.1 | 5.85 ib | 6 | 5.75 ib | |

| Parameter | gloss | roughness | haze | kis tau tus mob | kev xav | ||

| 35 ± 10 | 0.16 ± 0.02 | 17 ± 2 | > 89% | ~ 1% | |||

| 50 ± 10 | 0.13 ± 0.02 | 11 ± 2 | > 89% | ~ 1% | |||

| 70 ± 10 | 0.09 ± 0.02 | 6 ± 1 | > 89% | ~ 1% | |||

| 90 ± 10 | 0.07 ± 0.01 | 2.5 ± 0.5 | > 89% | ~ 1% | |||

| 110 ± 10 | 0.05 ± 0.01 | 1.5 ± 0.5 | > 89% | ~ 1% | |||

| Impact test | Thickness | steel pob luj (g) | qhov siab (cm) | ||||

| 0.7mm ib | 130 | 35 | |||||

| 1.1 hli | 130 | 50 | |||||

| 1.5 hli | 130 | 60 | |||||

| 2 hli | 270 | 50 | |||||

| 3mm ib | 540 | 60 | |||||

| 4mm ib | 540 | 80 | |||||

| 5mm ib | 1040 | 80 | |||||

| 6mm ib | 1040 | 100 | |||||

| Hardness | > 7 H | ||||||

|

| AG txheej txheej | AG tshuaj etching | |||||

| Anti-corrosion xeem | NaCL concentration 5%: | N/A | |||||

| Humidity resistance test | 60 ℃, 90% RH, 48 teev | N/A | |||||

| Abrasion xeem | 0000 #fsteel wool nrog 100ogf, 6000cycles, 40cycles / min | N/A | |||||

Kev ua haujlwm

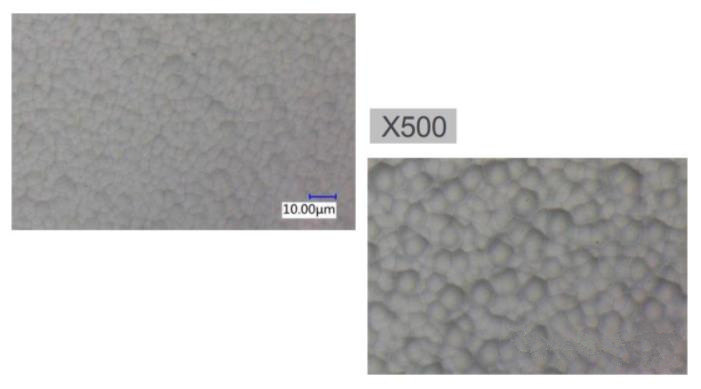

Anti-glare iav, hu ua AG iav, yog ib hom iav nrog kev kho tshwj xeeb ntawm lub iav nto.Lub hauv paus ntsiab lus yog ua cov txheej txheem zoo tshaj plaws ntawm ib qho lossis ob sab kom nws muaj qhov cuam tshuam qis dua li cov iav zoo tib yam, yog li txo qhov cuam tshuam ntawm lub teeb pom kev zoo, txhim kho qhov pom tseeb ntawm daim duab, txo qhov kev xav ntawm lub vijtsam, thiab ua kom cov duab huv thiab ntau qhov tseeb, tso cai rau cov neeg saib kom txaus siab rau qhov pom kev zoo dua.

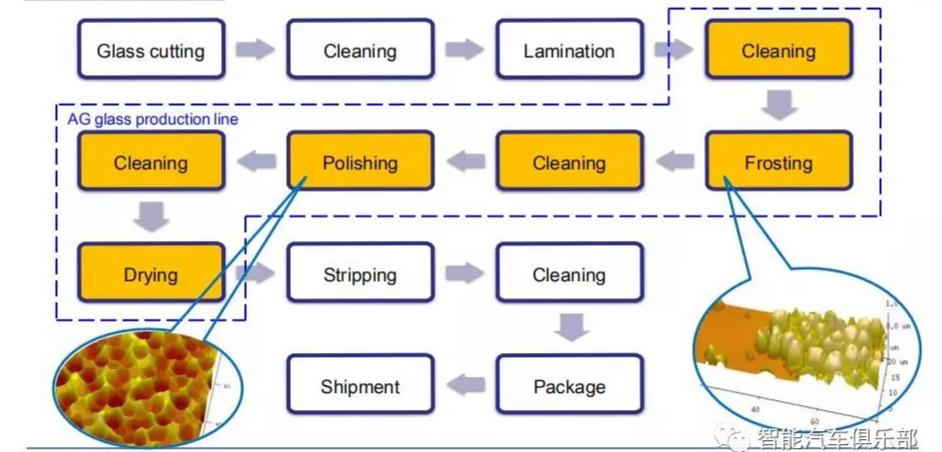

Lub hauv paus ntsiab lus ntawm AG iav yog muab faib ua AG lub cev tshuaj tsuag txheej thiab AG tshuaj etching

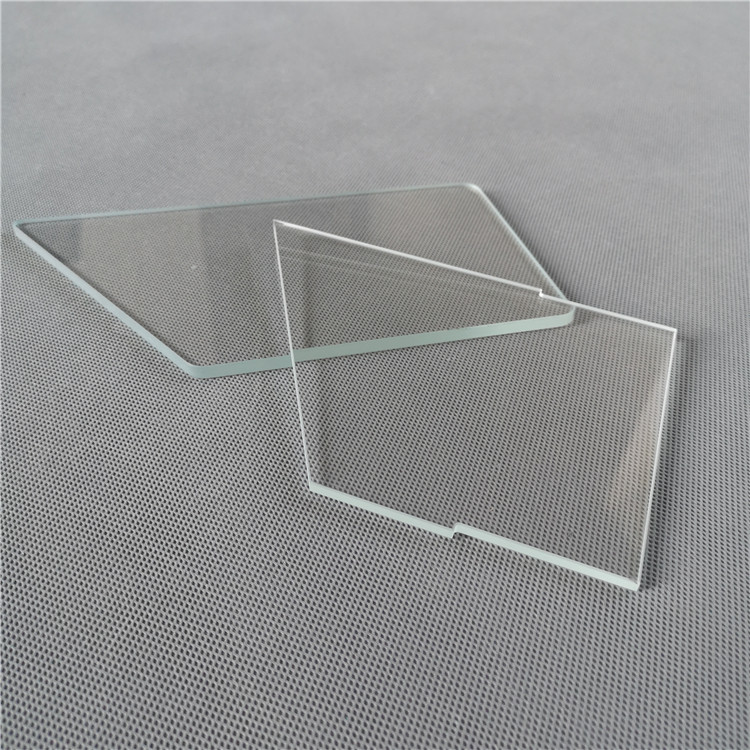

1. AG txau txheej iav

Nws txhais tau hais tias los ntawm kev siv lub zog los yog lub zog centrifugal, cov khoom xws li sub-micron silica yog uniformly coated rau ntawm iav nto los ntawm ib rab phom los yog ib tug disc atomizer, thiab tom qab cua sov thiab kho kev kho mob, ib txheej ntawm hais yog tsim nyob rau hauv lub khob. nto.Diffuse reflection ntawm lub teeb kom ua tiav cov nyhuv anti-glare

Raws li nws yog txau ib txheej rau ntawm iav, yog li iav thickness yuav me ntsis thicker tom qab txheej.

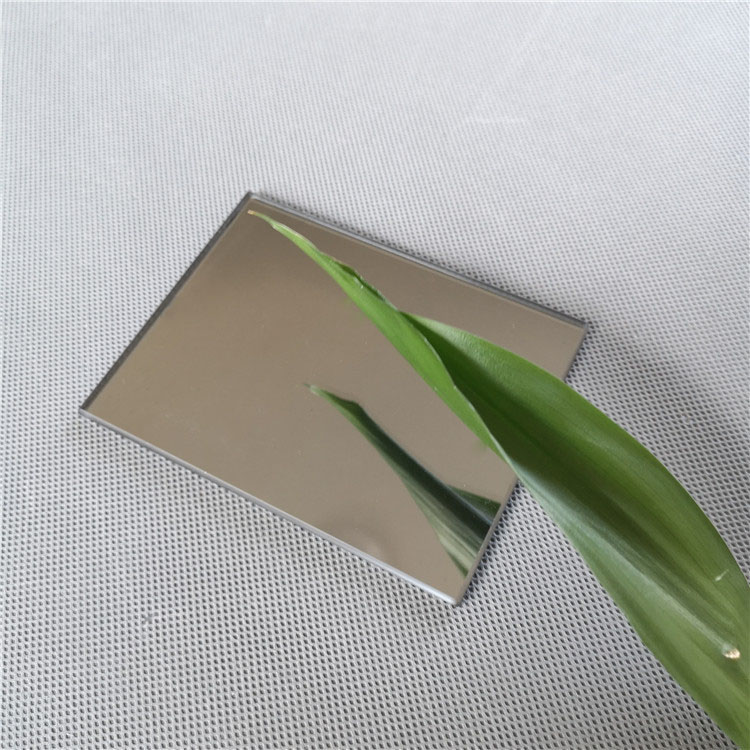

2. AG tshuaj etching iav.

Nws hais txog kev siv tshuaj tiv thaiv.it yuav tsum muaj cov tshuaj xws li hydrofluoric acid, hydrochloric acid, thiab sulfuric acid rau etching iav nto los ntawm glossy rau matt nrog micron particle nto, uas yog qhov tshwm sim ntawm kev sib xyaw ua ke ntawm ionization equilibrium, tshuaj. tshuaj tiv thaiv, dissolution thiab recrystallization, ion hloov thiab lwm yam tshuaj.

Raws li nws yog etching iav nto, yog li iav thickness yuav me ntsis thinner dua ua ntej.

Rau kev siv hluav taws xob lossis EMI tiv thaiv lub hom phiaj, peb tuaj yeem ntxiv ITO lossis FTO txheej.

Rau cov tshuaj tiv thaiv glare, peb tuaj yeem txais cov tshuaj tiv thaiv glare txheej ua ke los txhim kho lub teeb pom kev zoo.

Rau cov tshuaj oleophobic, anti ntiv tes luam ntawv txheej tuaj yeem ua tauzoo tshaj plawskev sib xyaw ua ke los txhim kho kev xav kov thiab ua kom lub vijtsam kov tau yooj yim dua los ntxuav.

AG (anti glare) iav VS AR (anti reflective) iav, qhov txawv yog dab tsi, qhov twg zoo dua.nyeem ntxiv

Daim ntawv thov cuam tshuam

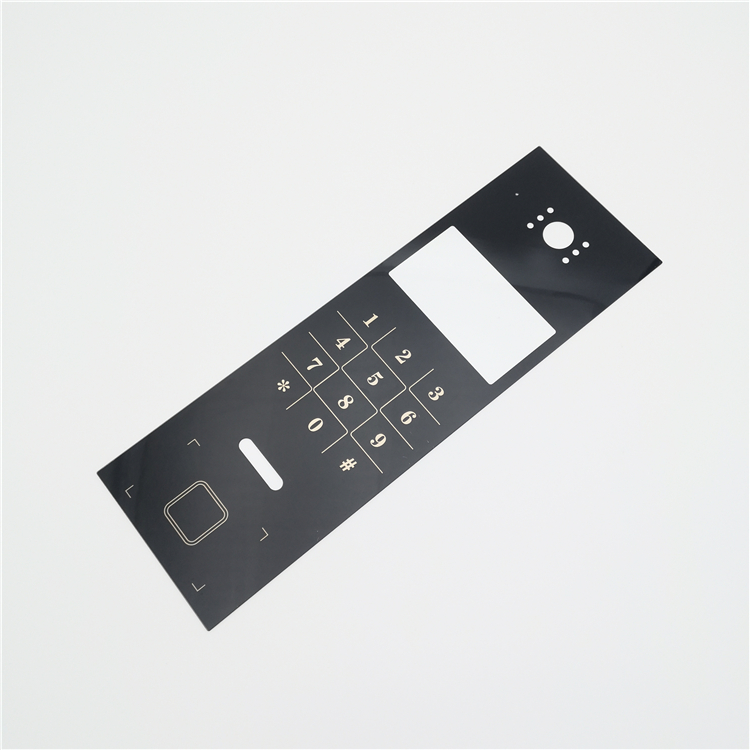

Tshuaj resistant anti glare iav rau industrial kov vaj huam sib luag

Loj loj los tiv thaiv glare iav rau digital signage kov cov ntxaij vab tshaus

Tsis glare iav npog lens rau tsheb navigation kov npo