omenala 2mm mgbochi glare iko maka touchscreens

Data teknụzụ

| Ọkpụrụkpụ | akụrụngwa | spraying mkpuchi | chemical etching | ||||

| elu | ala | elu | ala | elu | ala | ||

| 0.7mm | 0.75 | 0.62 | 0.8 | 0.67 | 0.7 | 0.57 | |

| 1.1mm | 1.05 | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5mm | 1.58 | 1.42 | 1.63 | 1.47 | 1.53 | 1.37 | |

| 2mm | 2.05 | 1.85 | 2.1 | 1.9 | 2 | 1.8 | |

| 3mm | 3.1 | 2.85 | 3.15 | 2.9 | 3.05 | 2.8 | |

| 4mm | 4.05 | 3.8 | 4.1 | 3.85 | 4 | 3.75 | |

| 5mm | 5.05 | 4.8 | 5.1 | 4.85 | 5 | 4.75 | |

| 6mm | 6.05 | 5.8 | 6.1 | 5.85 | 6 | 5.75 | |

| Oke | kenkowaputa | isi ike | haze | nnyefe | ntụgharị uche | ||

| 35±10 | 0.16± 0.02 | 17±2 | >89% | ~ 1% | |||

| 50±10 | 0.13 ± 0.02 | 11±2 | >89% | ~ 1% | |||

| 70±10 | 0.09± 0.02 | 6±1 | >89% | ~ 1% | |||

| 90±10 | 0.07± 0.01 | 2.5±0.5 | >89% | ~ 1% | |||

| 110±10 | 0.05± 0.01 | 1.5 ± 0.5 | >89% | ~ 1% | |||

| Nnwale mmetụta | Ọkpụrụkpụ | arọ bọọlụ ígwè(g) | elu (cm) | ||||

| 0.7mm | 130 | 35 | |||||

| 1.1mm | 130 | 50 | |||||

| 1.5mm | 130 | 60 | |||||

| 2mm | 270 | 50 | |||||

| 3mm | 540 | 60 | |||||

| 4mm | 540 | 80 | |||||

| 5mm | 1040 | 80 | |||||

| 6mm | 1040 | 100 | |||||

| Isi ike | >7H | ||||||

|

| AG spraying mkpuchi | Mgbanwe nke ọnụ ahịa nke AG Chemical | |||||

| Nnwale mgbochi corsion | Ntinye uche NaCL 5%: | N/A | |||||

| Nnwale nguzogide iru mmiri | 60 ℃, 90% RH, awa 48 | N/A | |||||

| Nnwale abrasion | 0000#fsteel ajị nwere 100ogf ,6000cycles,40cycles/min | N/A | |||||

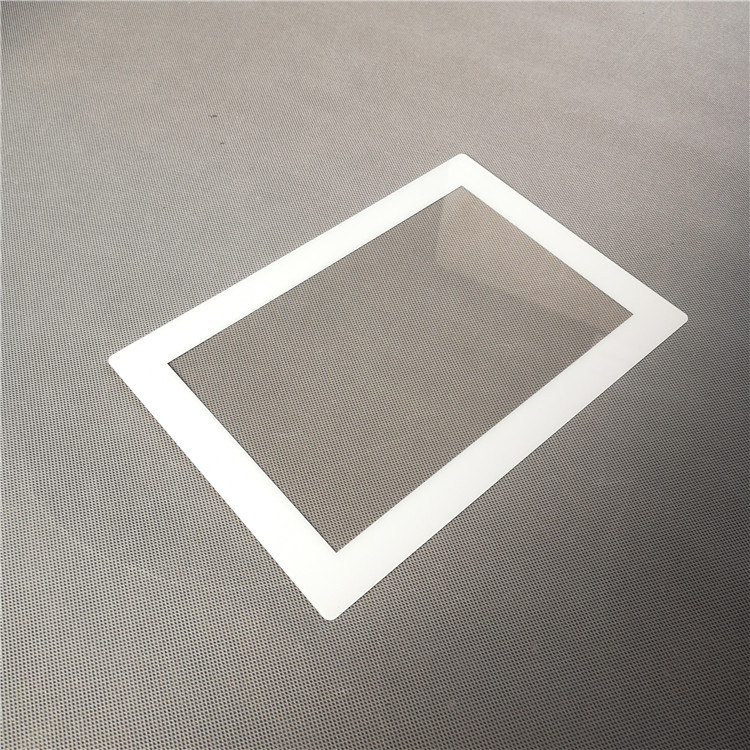

Nhazi

Igwe mgbochi na-egbuke egbuke, nke a na-akpọ AG glass, bụ ụdị iko nwere ọgwụgwọ pụrụ iche n'elu iko.Ụkpụrụ bụ ịhazi ihe mkpuchi dị elu na otu ma ọ bụ n'akụkụ abụọ iji mee ka ọ nwee mmetụta dị ala karịa iko nkịtị, si otú ahụ belata nnyonye anya nke ìhè ambient, na-eme ka ihe doo anya nke foto ahụ, na-ebelata ihuenyo ihuenyo, na-eme ka ihe oyiyi ahụ dị ọcha. ihe ezi uche dị na ya, na-enye ndị na-ekiri ya ohere ịnụ ụtọ mmetụta ọhụụ ka mma.

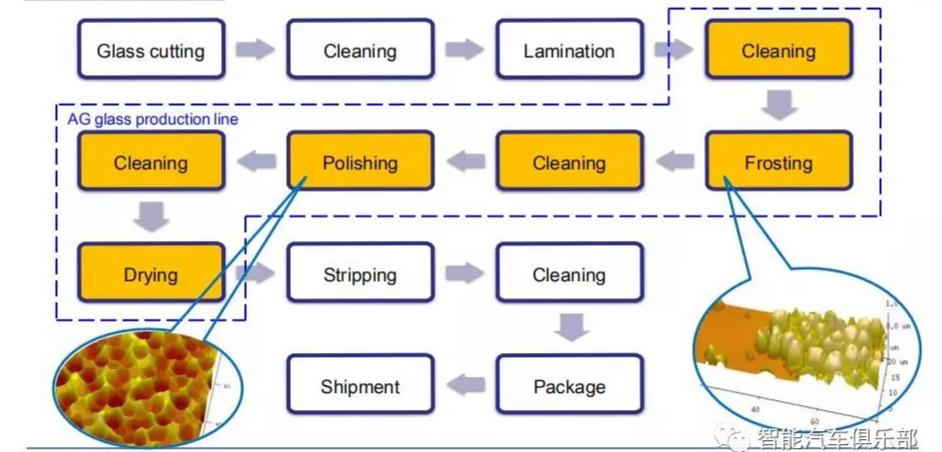

A na-ekewa ụkpụrụ mmepụta nke iko AG ka ọ bụrụ mkpuchi mkpuchi anụ ahụ AG na AG chemical etching

1. AG spraying mkpuchi iko

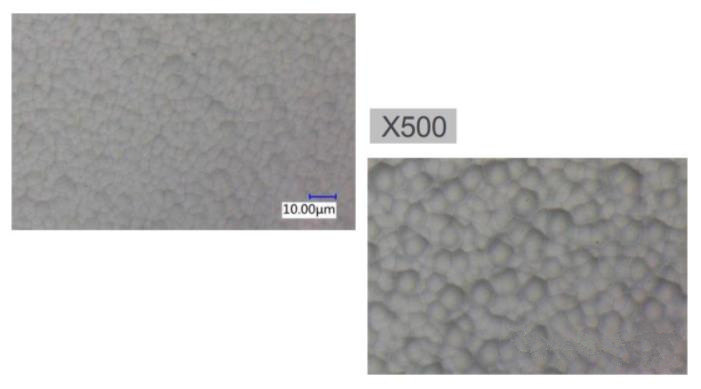

Ọ pụtara na site na nrụgide ma ọ bụ ike centrifugal, a na-ekpuchi ihe ndị dị ka sub-micron silica n'otu n'otu n'elu ugegbe site na egbe ịgba ma ọ bụ atomizer diski, na mgbe ikpo ọkụ na ọgwụgwọ ọgwụgwọ, a na-emepụta ihe dị iche iche na iko. elu.Na-agbasa echiche nke ìhè iji nweta mmetụta mgbochi ọkụ

Dị ka ọ na-efesa mkpuchi n'elu iko, otú ahụ ka ọkpụrụkpụ iko ga-adị ntakịrị karịa mgbe mkpuchi.

2. AG chemical etching iko.

Ọ na-ezo aka na ojiji nke chemical reactions.it chọrọ chemicals dị ka hydrofluoric acid, hydrochloric acid, na sulfuric acid ka etching iko elu si kenkowaputa ka matt na micron urughuru elu, nke bụ n'ihi nke jikọtara omume nke ionization equilibrium, chemical. mmeghachi omume, mgbasa na recrystallization, nnọchi ion na mmeghachi omume ndị ọzọ.

Ka ọ na-etching elu ugegbe, otú ọkpụrụkpụ iko ga-adị ntakịrị ntakịrị karịa ka ọ dị na mbụ.

Maka ebumnuche nchekwa ma ọ bụ EMI, anyị nwere ike itinye mkpuchi ITO ma ọ bụ FTO.

Maka ngwọta mgbochi glare, anyị nwere ike ijikọ mkpuchi mgbochi glare ọnụ iji melite njikwa ntụgharị ọkụ.

Maka ngwọta oleophobic, mkpuchi mkpuchi mkpịsị aka nwere ike ịbụkacha mmaNchikota iji meziwanye mmetụta mmetụ ma mee ka ihuenyo mmetụ dị mfe ihicha.

AG (mgbochi glare) iko VS AR (mgbochi reflective) iko, kedu ihe dị iche, nke ka mma.GỤKWUO

Ngwa emetụtara

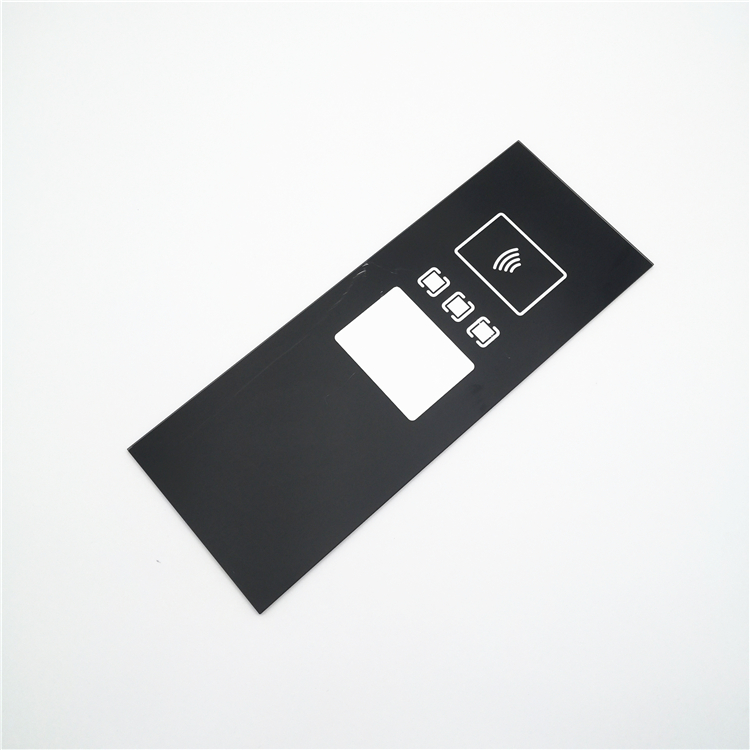

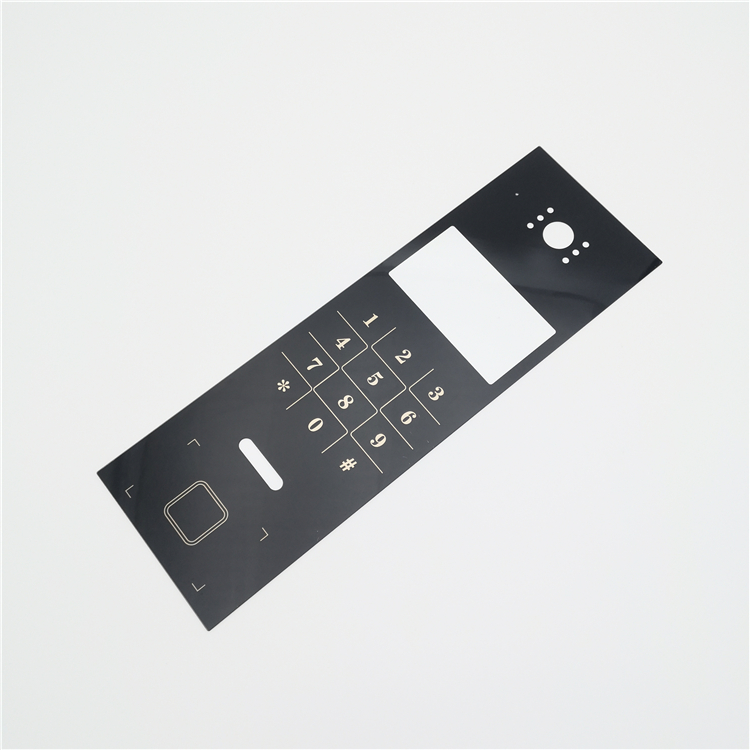

Igwe na-eguzogide ọgwụ mgbochi maka ụlọ ọrụ mmetụ aka

Nnukwu iko mgbochi na-egbuke egbuke maka ihuenyo mmetụ akara dijitalụ

Igwe mkpuchi mkpuchi na-enweghị ọkụ maka ihuenyo mmetụ igodo ụgbọ ala