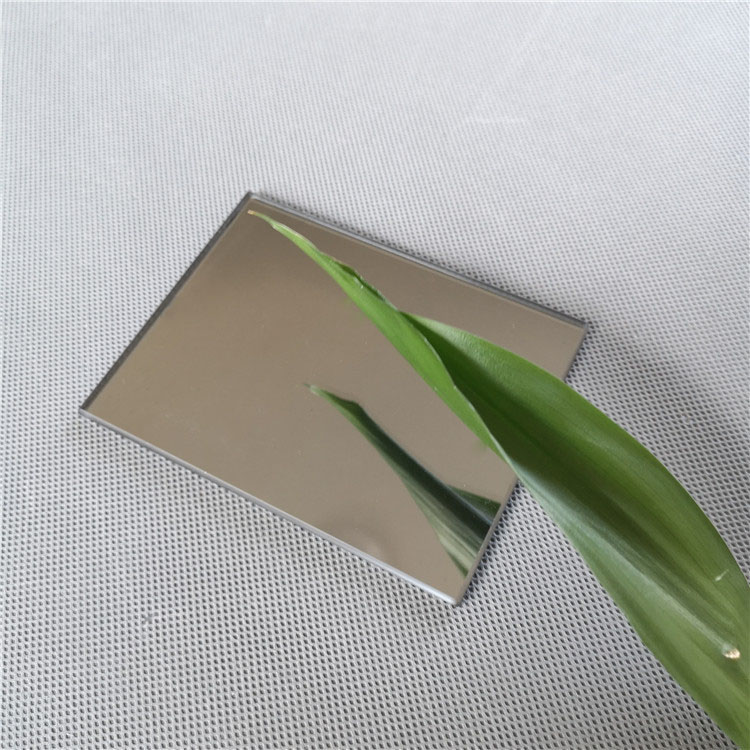

ito coated glass,ito conductive glass,ito cover glass

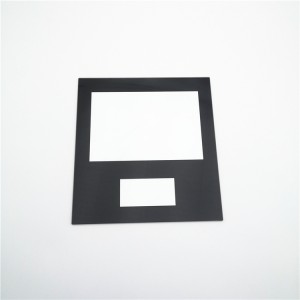

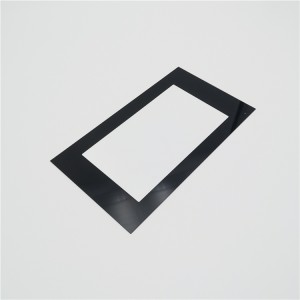

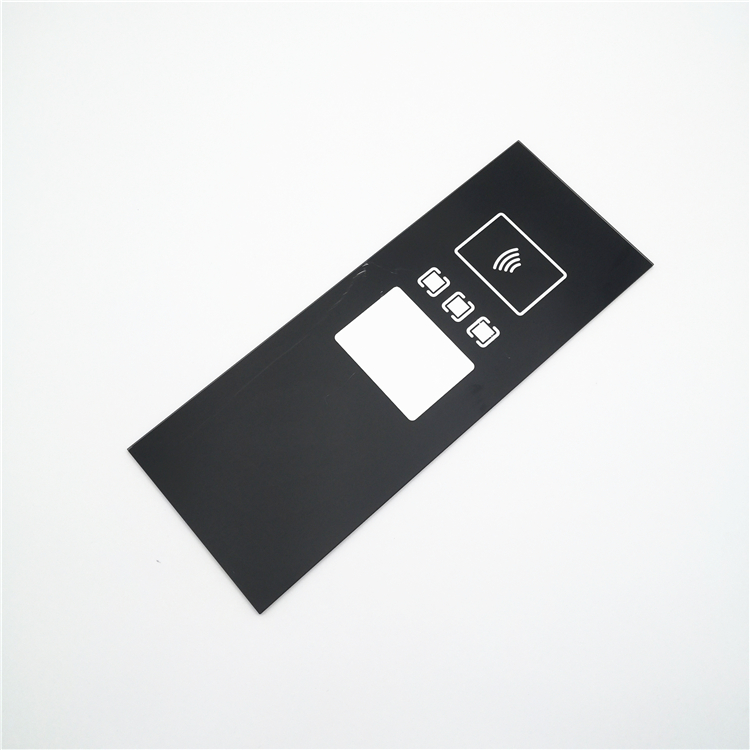

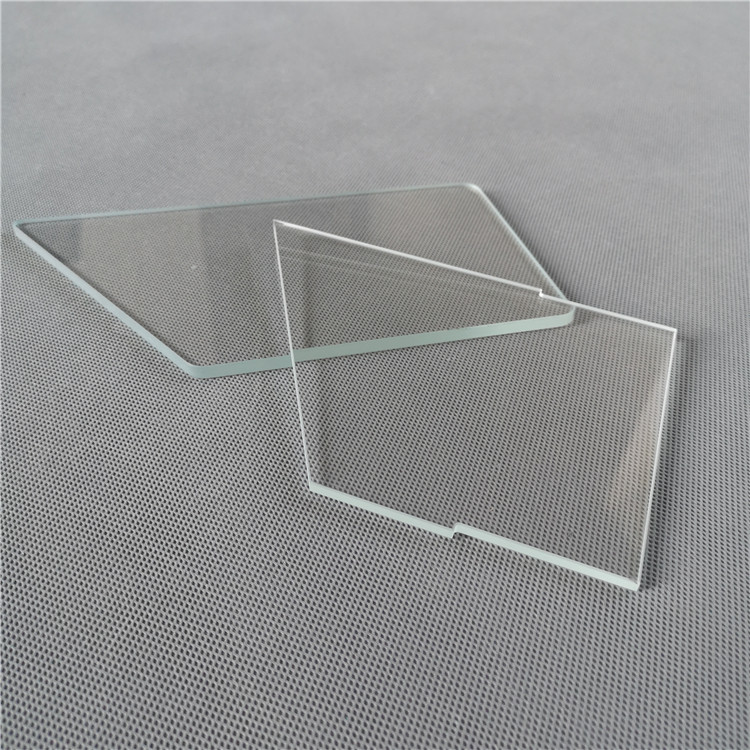

Products Pics

ITO conductive coated glass is made by spreading silicon dioxide (SiO2) and indium tin oxide (commonly known as ITO) layer by magnetron sputtering technology on glass substrate under entirely vacuumed condition,making coated face conductive, ITO is a metal compound with good transparent and conductive properties.

Technical data

|

ITO glass thickness |

0.4mm,0.5mm,0.55mm,0.7mm,1mm,1.1mm,2mm,3mm,4mm |

||||||||

|

resistance |

3-5Ω |

7-10Ω |

12-18Ω |

20-30Ω |

30-50Ω |

50-80Ω |

60-120Ω |

100-200Ω |

200-500Ω |

|

coating thickness |

2000-2200Å |

1600-1700Å |

1200-1300Å |

650-750Å |

350-450Å |

200-300Å |

150-250Å |

100-150Å |

30-100Å |

|

Glass resistance |

|||

|

Resistance type |

low resistance |

normal resistance |

high resistance |

|

Definition |

<60Ω |

60-150Ω |

150-500Ω |

|

Application |

High resistance glass is generally used for electrostatic protection and touch screen production |

Ordinary resistance glass is generally used for TN type liquid crystal display and electronic anti-interference(EMI shielding) |

Low resistance glass is generally used in STN liquid crystal displays and transparent circuit boards |

|

Functional test and reliability test |

|

|

Tolerance |

±0.2mm |

|

Warpage |

thickness <0.55mm,warpage≤0.15% thickness>0.7mm,warpage≤0.15% |

|

Z-T vertical |

≤1° |

|

Hardness |

>7H |

|

Coating Abrasion test |

0000#steel wool with 1000gf,6000cycles,40cycles/min |

|

Anti corrsion test(salt spray test) |

NaCL concentration 5%: Temperature: 35°C Experiment time: 5min resistance change≤10% |

|

Humidity resistance test |

60℃,90%RH,48 hours resistance change≤10% |

|

Acid resistance test |

HCL concentration:6%,Temperature: 35°C Experiment time: 5min resistance change≤10% |

|

Alkali resistance test |

NaOH concentration:10%,Temperature: 60°C Experiment time: 5min resistance change≤10% |

|

Themal stability |

Temperature:300°C heating time:30min resistance change≤300% |

Processing

Si02 layer:

(1) The role of the SiO2 layer:

The main purpose is to prevent the metal ions in the soda-calcium substrate from diffusing into the ITO layer. It affects the conductivity of the ITO layer.

(2) Film thickness of SiO2 layer:

The standard film thickness is generally 250 ± 50 Å

(3) Other components in the SiO2 layer:

Usually, in order to improve the transmittance of ITO glass, a certain proportion of SiN4 is doped into SiO2.

Related application

Ito Glass For Military Emi Shielding Display

Ito Coated Glass For Hmi Touch Panel

Tempered Ito Conductive Glass For Body Scale