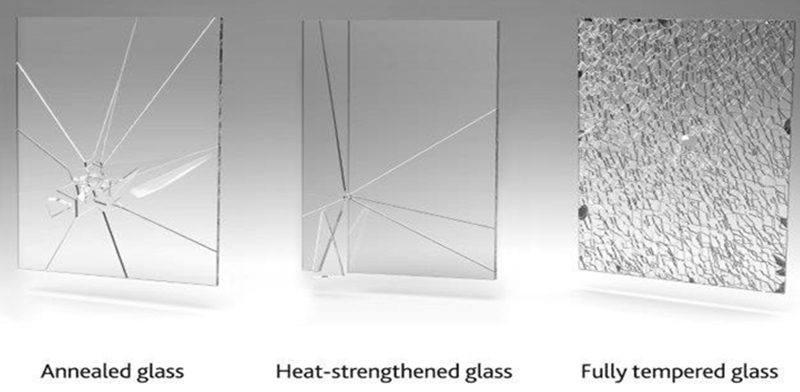

Annealed glass

Normal glass without any tempered processing,break easily.

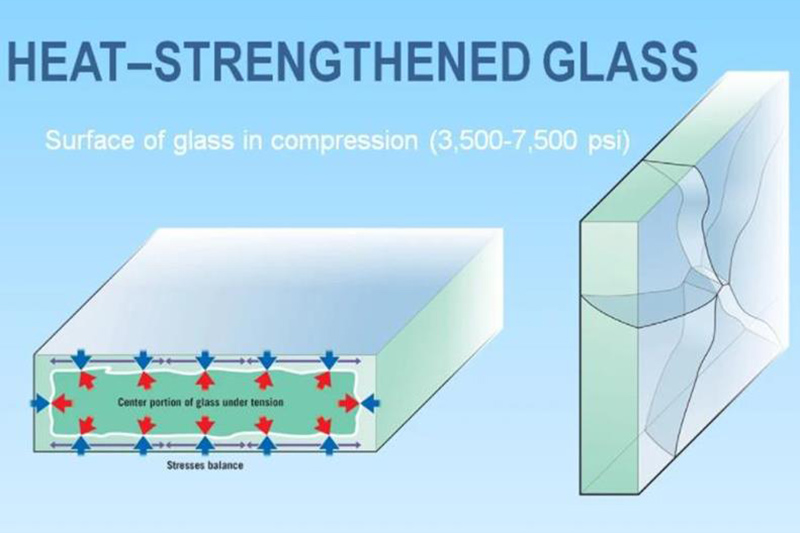

Heat strengthened glass

Two times as stronger as annealed glass, relevantly resistant to breakage, It is applied to specific circumstance,such as some flat glass like 3mm float glass or glass strip,can not withstand the high air pressure during heat tempering then deformation or severe warpage will happen on glass,then using heat strengthening will be better way.

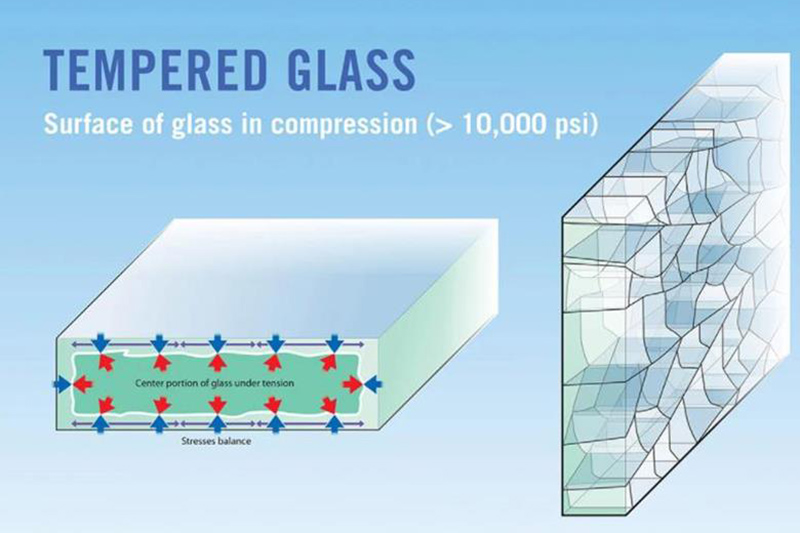

Fully tempered glass

Also called safety glass or heat tempered glass,four times as strong as annealed glass,it is applied to project which request high impact strength and thermal shock resistance, it will broken into dice without sharp debris.

|

heat strengthened glass |

Thermal tempered glass |

||

|

similarity |

heating process |

1:Production using the same processing equipment 2:Further cutting and drilling unworkable |

|

|

Difference |

cooling process |

With heat strengthened glass, the cooling process is slower, which means the compression strength is lower. In the end, heat-strengthened glass is approximately twice as strong as annealed, or untreated, glass. |

With tempered glass, the cooling process is accelerated to create higher surface compression (the dimension of force or energy per unit area) and/or edge compression in the glass. It is the air-quench temperature, volume and other variables that create a surface compression of at least 10,000 pounds per square inch (psi). This is the process that makes the glass four to five times stronger and safer than annealed or untreated glass. As a result, tempered glass is less likely to experience a thermal break. |

|

Application |

It is applied to specific circumstance,such as some flat glass like 3mm float glass or glass strip,can not withstand the high air pressure during cooling process then deformation or severe warpage will happen on glass |

it is applied to project which request high impact strength and thermal shock resistance |

|

|

glass flatness |

≤0.5mm (depend on size) |

≤1mm (depend on size) |

|

|

glass surface compression |

24-60MPa |

≥90MPa |

|

|

Fragmentation test |

|||

|

thermal shock resistance |

heating glass to 200℃ then put rapidly to 0℃ water without breaking |

heating glass to 100℃ then put rapidly to 0℃ water without breaking |

|

|

Impact resistance |

thermal tempered glass 2 times stronger than heat strengthened glass |

||

|

Temperature resistance |

thermal tempered glass 2 times stronger than heat strengthened glass |

||