caadadii 2mm dhaldhalaalka ka hortagga muraayadaha taabashada

Xogta farsamada

| Dhumucda | alaabta ceeriin | daahan buufinta | cuncun kiimikaad | ||||

| sare | hoose | sare | hoose | sare | hoose | ||

| 0.7mm | 0.75 | 0.62 | 0.8 | 0.67 | 0.7 | 0.57 | |

| 1.1mm | 1.05 | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5mm | 1.58 | 1.42 | 1.63 | 1.47 | 1.53 | 1.37 | |

| 2mm | 2.05 | 1.85 | 2.1 | 1.9 | 2 | 1.8 | |

| 3mm | 3.1 | 2.85 | 3.15 | 2.9 | 3.05 | 2.8 | |

| 4mm | 4.05 | 3.8 | 4.1 | 3.85 | 4 | 3.75 | |

| 5mm | 5.05 | 4.8 | 5.1 | 4.85 | 5 | 4.75 | |

| 6mm | 6.05 | 5.8 | 6.1 | 5.85 | 6 | 5.75 | |

| Halbeegga | dhalaalid | qallafsanaan | cidhiidhi | gudbinta | milicsi | ||

| 35±10 | 0.16 ± 0.02 | 17±2 | >89% | ~ 1% | |||

| 50± 10 | 0.13 ± 0.02 | 11±2 | >89% | ~ 1% | |||

| 70± 10 | 0.09±0.02 | 6±1 | >89% | ~ 1% | |||

| 90±10 | 0.07±0.01 | 2.5±0.5 | >89% | ~ 1% | |||

| 110± 10 | 0.05 ± 0.01 | 1.5±0.5 | >89% | ~ 1% | |||

| Tijaabada saamaynta | Dhumucda | Miisaanka kubbadda birta (g) | dhererka (cm) | ||||

| 0.7mm | 130 | 35 | |||||

| 1.1mm | 130 | 50 | |||||

| 1.5mm | 130 | 60 | |||||

| 2mm | 270 | 50 | |||||

| 3mm | 540 | 60 | |||||

| 4mm | 540 | 80 | |||||

| 5mm | 1040 | 80 | |||||

| 6mm | 1040 | 100 | |||||

| Adag | >7H | ||||||

|

| daahan buufinta AG | Etching kiimikaad AG | |||||

| Baaritaanka daxalka | Isku-duubnida NaCL 5%: | N/A | |||||

| Tijaabada iska caabbinta qoyaanka | 60 ℃, 90% RH, 48 saacadood | N/A | |||||

| Baaritaanka nabarrada | 0000#fsteel dhogor ah oo leh 100ogf ,6000cycles,40cycles/min | N/A | |||||

Habaynta

Muraayadaha ka-hortagga muraayadda, oo loo yaqaanno AG galaas, waa nooc muraayad ah oo leh daaweyn gaar ah oo ku taal dusha dhalada.Mabda'a ayaa ah in lagu farsameeyo dahaadhka tayada sare leh ee hal ama labada dhinacba si ay u yeeshaan muuqaal ka hooseeya muraayadda caadiga ah, taas oo yaraynaysa faragelinta iftiinka iftiinka, hagaajinta caddaynta sawirka, yaraynta muraayadda muraayadda, iyo samaynta sawirka nadiifka ah Xaqiiqo badan, taas oo u oggolaanaysa daawadayaasha inay ku raaxaystaan saameyn muuqaal ah oo wanaagsan.

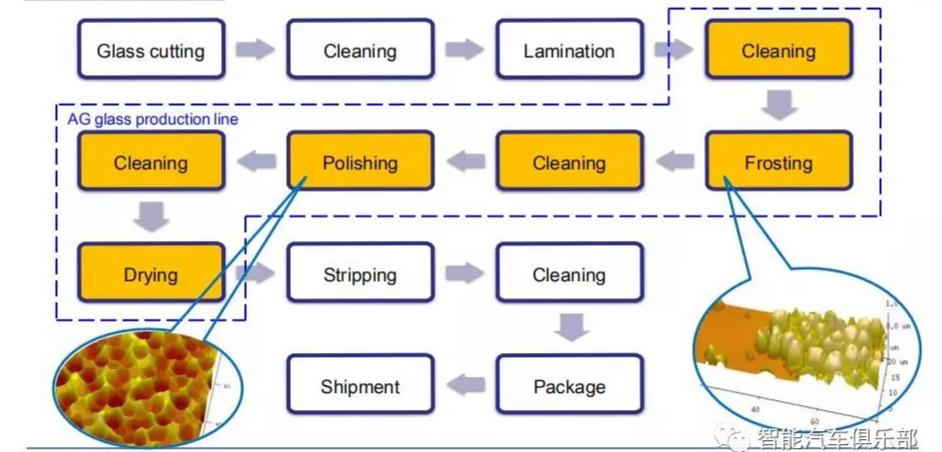

Mabda'a wax soo saarka ee muraayadda AG waxay u qaybsan tahay AG daahan buufin jireed iyo AG kiimiko etching

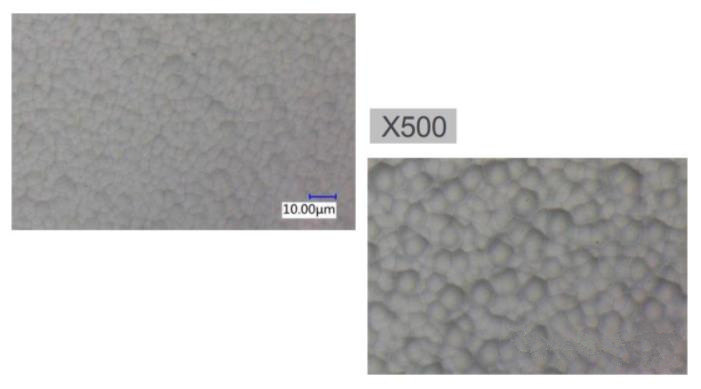

1. AG buufin muraayadda daahan

Waxaa loola jeedaa in cadaadiska ama xoogga centrifugal, qaybo ka mid ah silica-sub-micron ay si isku mid ah ugu dahaaran yihiin dusha muraayadda iyada oo loo marayo qori buufin ama atomizer disc ah, iyo kuleylka iyo daaweynta daaweynta ka dib, lakabka qayb ka mid ah ayaa lagu sameeyay muraayadda. dusha sare.Kala firdhiso iftiinka iftiinka si loo gaaro saameyn liddi ku ah dhaldhalaalka

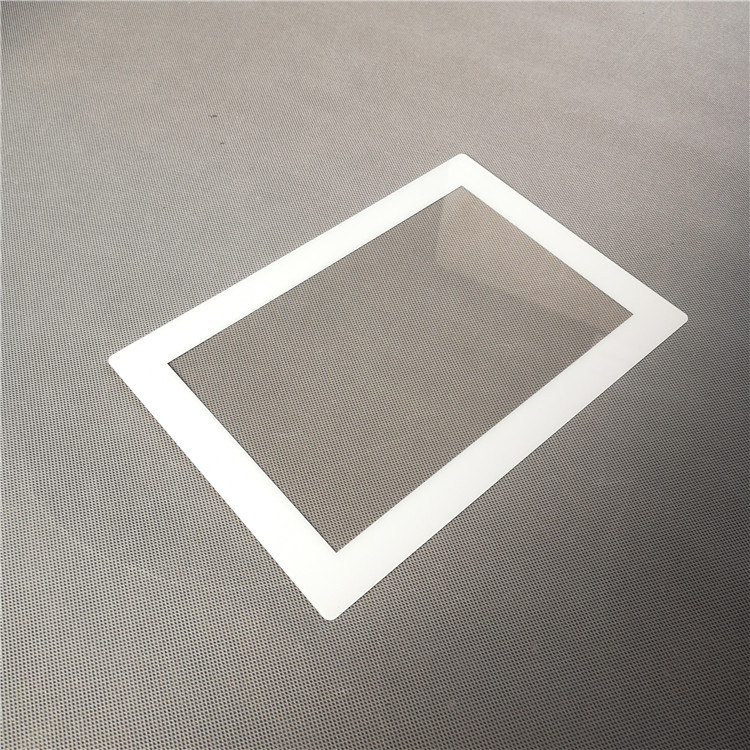

Sida ay ku buufinayso daahan dusha muraayadda, markaa dhumucda dhaladu waxay noqon doontaa wax yar dhumucdi ka dib daahan.

2. AG kiimikada etching galaas.

Waxa loola jeedaa isticmaalka falcelinta kiimikaad. Waxay u baahan tahay kiimikooyin sida hydrofluoric acid, hydrochloric acid, iyo sulfuric acid si ay u xoqdo dusha dhalada ee dhalaalaysa ilaa matt dusha sare ee walxaha micron, taas oo ah natiijada ficil isku dhafan ee dheellitirka ionization, kiimikaad falcelinta, kala dirida iyo recrystalization, beddelka ion iyo falcelin kale.

Sida ay u qurxinayso dusha muraayadda, markaa dhumucda dhaladu waxay noqon doontaa mid ka khafiifsan sidii hore.

Ujeeddada gaashaandhigga ama EMI, waxaan ku dari karnaa daahan ITO ama FTO.

Xalka ka hortagga dhaldhalaalka, waxaan si wada jir ah u qaadan karnaa daahan ka-hortagga dhaldhalaalka si aan u wanaajino xakamaynta iftiinka iftiinka.

Xalka oleophobic, dahaarka daabacaadda farta ayaa noqon karaugu fiicanisku darka si loo hagaajiyo dareenka taabashada iyo in shaashadda taabashada si sahlan loo nadiifiyo.

AG (anti glare) galaas VS AR (anti milicsiga) galaas, waa maxay faraqa u dhexeeya, kee baa ka wanaagsan.Akhri wax dheeraad ah

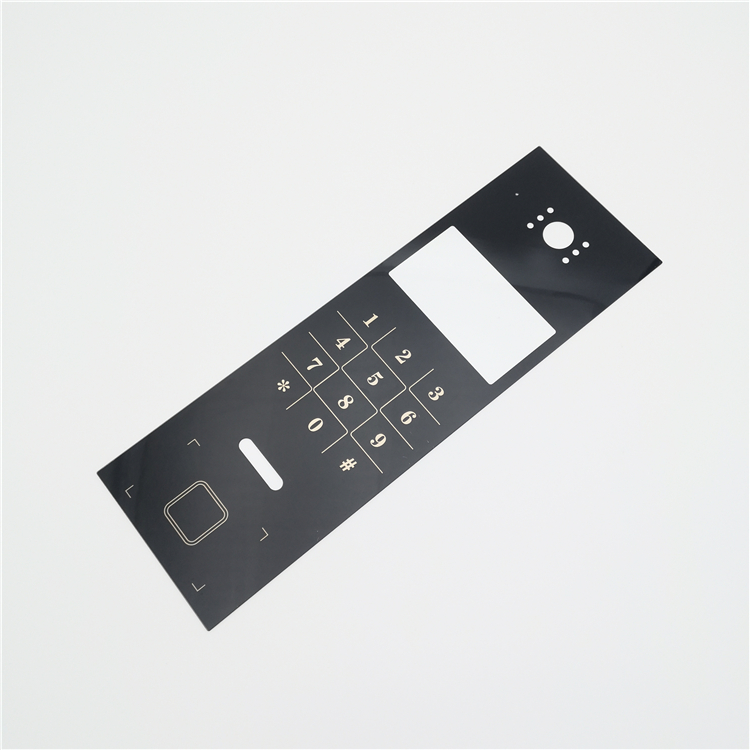

Codsiga la xidhiidha

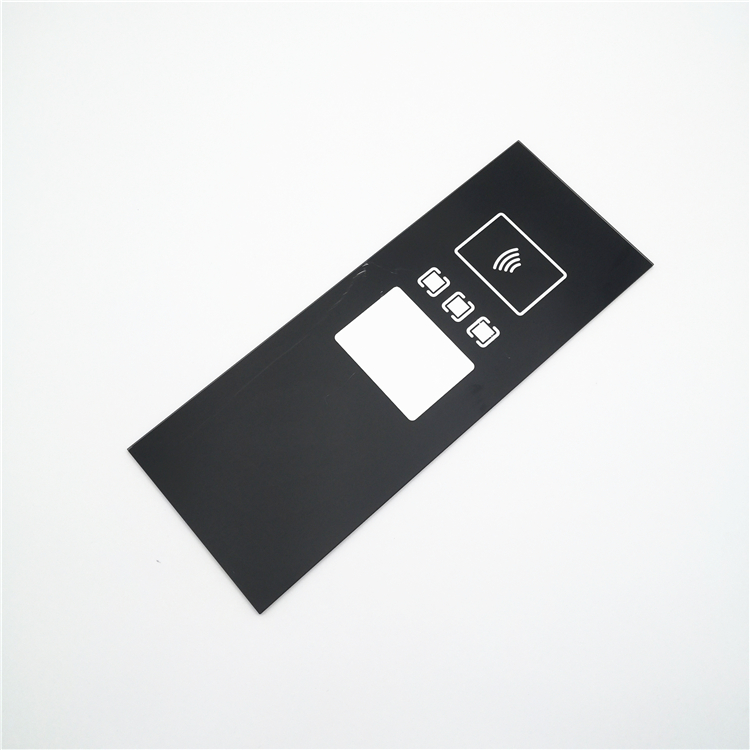

Kiimikada u adkeysiga muraayadda dhaldhalaalka ee guddiga taabashada warshadaha

Muraayadaha ka hortagga dhaldhalaalka ee cabbirka weyn ee muraayadaha taabashada calaamadaha dhijitaalka ah

Muraayadaha daboolka muraayadda aan dhalaalaynin ee muraayadda taabasho ee baabuurka