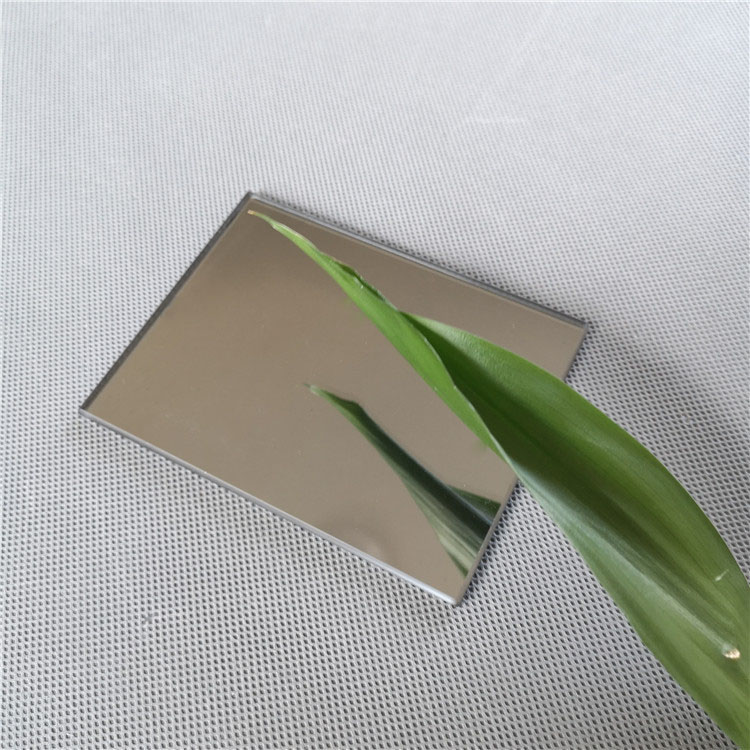

galaaska dahaarka leh,ito conductive galaas,ito cover galaaska

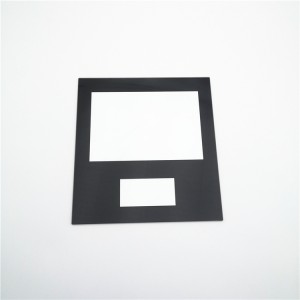

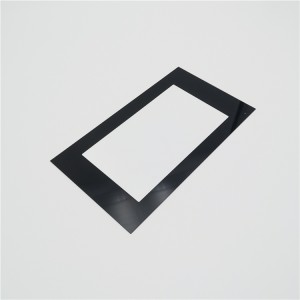

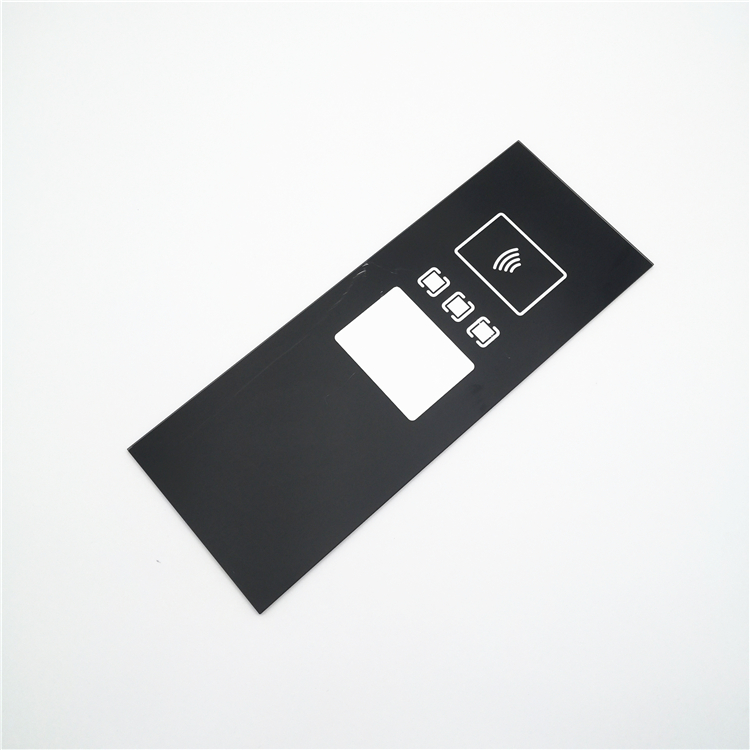

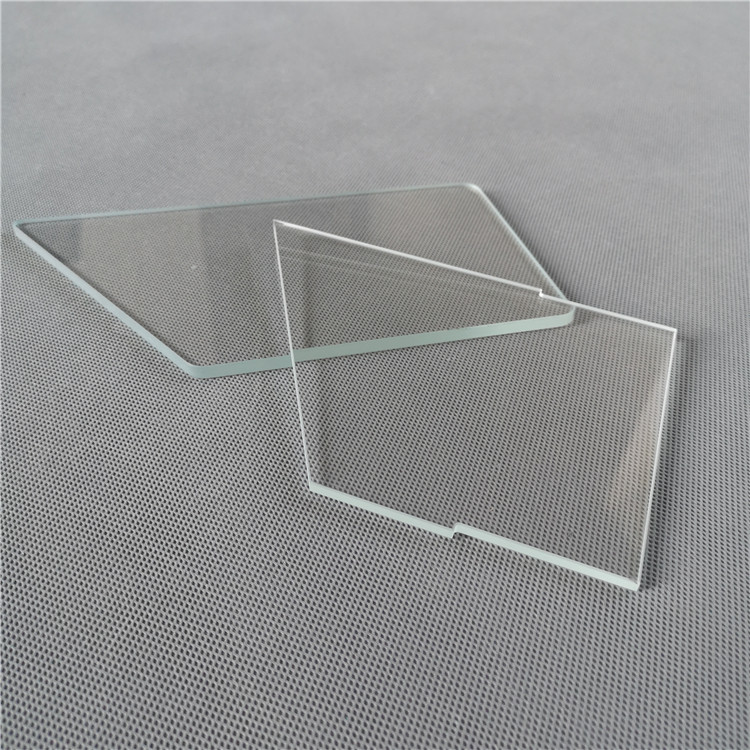

Sawirada Alaabta

Muraayada dahaarka leh ee ITO waxaa lagu sameeyaa iyadoo la faafiyo silikoon dioxide (SiO2) iyo indium tin oxide (oo loo yaqaan ITO) lakabka tignoolajiyada magnetron sputtering on substrate galaaska hoostiisa xaalad gebi ahaan vacuumed, samaynta dahaarka ah conductive wejiga, ITO waa xarun bir ah oo leh hufan wanaagsan iyo guryaha qabanqaabada.

Xogta farsamada

| dhumucda dhalada ITO | 0.4mm,0.5mm,0.55mm,0.7mm,1mm,1.1mm,2mm,3mm,4mm | ||||||||

| iska caabin | 3-5Ω | 7-10Ω | 12-18Ω | 20-30Ω | 30-50Ω | 50-80Ω | 60-120Ω | 100-200Ω | 200-500Ω |

| dhumucda daahan | 2000-2200Å | 1600-1700Å | 1200-1300Å | 650-750Å | 350-450Å | 200-300Å | 150-250Å | 100-150Å | 30-100Å |

| Iska caabin dhalo | |||

| Nooca iska caabinta | iska caabin hoose | iska caabin caadi ah | iska caabin sare |

| Qeexid | <60Ω | 60-150Ω | 150-500Ω |

| Codsiga | Muraayadaha caabbinta sare leh ayaa guud ahaan loo isticmaalaa ilaalinta korantada iyo wax soo saarka shaashadda taabashada | Muraayadaha iska caabbinta caadiga ah waxaa guud ahaan loo isticmaalaa nooca TN ee muraayadda dareeraha ah iyo ka-hortagga elektarooniga ah (EMI gaashaanka) | Muraayadaha iska caabbinta hooseeya ayaa guud ahaan loo adeegsadaa bandhigyada kristal dareeraha ah ee STN iyo looxyada wareegga ee hufan |

| Imtixaanka shaqaynta iyo tijaabada isku halaynta | |

| Dulqaad | ±0.2mm |

| Warbog | dhumucdiisuna<0.55mm, bog dagaal≤0.15% dhumucdiisuna>0.7mm, bog dagaal≤0.15% |

| ZT toosan | ≤1° |

| Adag | >7H |

| Tijaabada abrasion ee dahaarka | 0000 # dhogor bir ah oo leh 1000gf,6000 baaskiil, 40 baaskiil/daqdi |

| Baaritaanka daxalka (tijaabada buufinta milixda) | NaCL fiirsashada 5%: Heerkulka: 35°C Waqtiga tijaabada: 5min isbeddelka caabbinta≤10% |

| Tijaabada iska caabbinta qoyaanka | 60℃,90% RH,48 saacadood oo iska caabin ah ayaa isbeddelay≤10% |

| Tijaabada caabbinta aysiidhka | Heerarka HCL: 6%, Heerkulka: 35°C Waqtiga tijaabada: 5min isbeddelka caabbinta≤10% |

| Tijaabada iska caabinta Alkali | NaOH-fiirsashada: 10%, Heerkulka: 60°C Waqtiga tijaabada: 5min isbeddelka caabbinta≤10% |

| Xasiloonida kuleylka | Heerkulka: 300°C wakhtiga kuleylka: 30min isbeddelka caabbinta≤300% |

Habaynta

Lakabka Si02:

(1) Doorka lakabka SiO2:

Ujeedada ugu weyni waa in laga hortago ion-yada birta ah ee ku jira substrate-ka-calcium inay ku faafiyaan lakabka ITO.Waxay saamaysaa hab-dhaqanka lakabka ITO.

(2) Dhumucda filimka lakabka SiO2:

Dhumucda filimka caadiga ah guud ahaan waa 250 ± 50 Å

(3) Qaybaha kale ee lakabka SiO2:

Caadi ahaan, si loo hagaajiyo gudbinta dhalada ITO, qayb gaar ah oo SiN4 ah ayaa lagu shubaa SiO2.

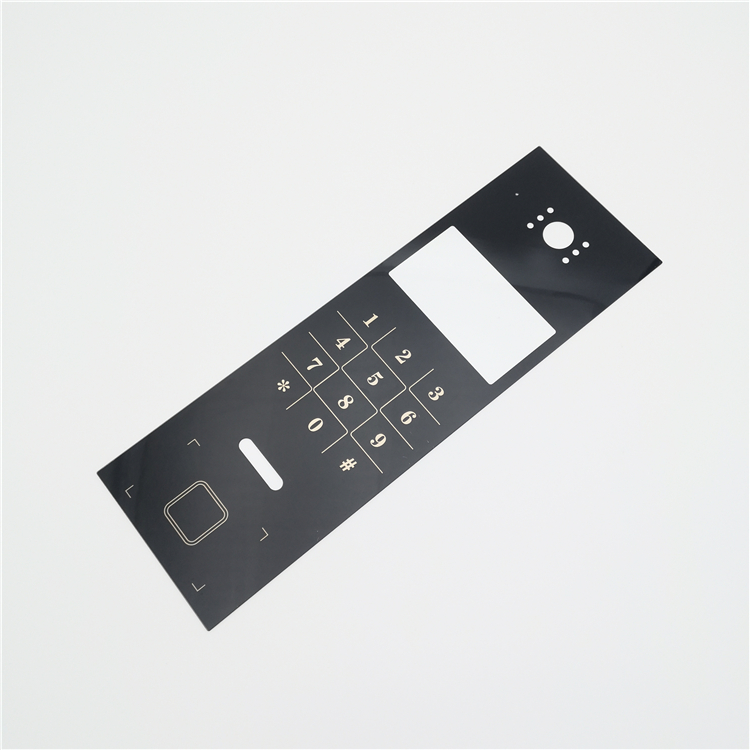

Codsiga la xidhiidha

Ito Glass oo loogu talagalay Bandhigga gaashaandhigga ee Emi

Muraayadaha Dahaarka leh ee Hmi Touch Panel

Muraayadaha wax qabad ee Ito ee Xanaaqay ee Miisaanka Jirka