Khalase ea antiglare bakeng sa fensetere ea pontšo

Lintlha tsa tekheniki

| Botenya | lisebelisoa tse so ntlafatsoe | ho fafatsa ho roala | etching ea lik'hemik'hale | ||||

| hodimo | tlase | hodimo | tlase | hodimo | tlase | ||

| 0.7 limilimithara | 0.75 | 0.62 | 0.8 | 0.67 | 0.7 | 0.57 | |

| 1.1 limilimithara | 1.05 | 1.15 | 1.1 | 1.2 | 1 | 1.1 | |

| 1.5 limilimithara | 1.58 | 1.42 | 1.63 | 1.47 | 1.53 | 1.37 | |

| 2mm | 2.05 | 1.85 | 2.1 | 1.9 | 2 | 1.8 | |

| 3mm | 3.1 | 2.85 | 3.15 | 2.9 | 3.05 | 2.8 | |

| 4mm | 4.05 | 3.8 | 4.1 | 3.85 | 4 | 3.75 | |

| 5mm | 5.05 | 4.8 | 5.1 | 4.85 | 5 | 4.75 | |

| 6mm | 6.05 | 5.8 | 6.1 | 5.85 | 6 | 5.75 | |

| Paramethara | kganya | makgwakgwa | haze | phetiso | ponahatso | ||

| 35±10 | 0.16±0.02 | 17±2 | >89% | ~1% | |||

| 50±10 | 0.13±0.02 | 11±2 | >89% | ~1% | |||

| 70±10 | 0.09±0.02 | 6±1 | >89% | ~1% | |||

| 90±10 | 0.07±0.01 | 2.5±0.5 | >89% | ~1% | |||

| 110±10 | 0.05±0.01 | 1.5±0.5 | >89% | ~1% | |||

| Teko ea tšusumetso | Botenya | boima ba bolo ea tšepe(g) | bophahamo(cm) | ||||

| 0.7 limilimithara | 130 | 35 | |||||

| 1.1 limilimithara | 130 | 50 | |||||

| 1.5 limilimithara | 130 | 60 | |||||

| 2mm | 270 | 50 | |||||

| 3mm | 540 | 60 | |||||

| 4mm | 540 | 80 | |||||

| 5mm | 1040 | 80 | |||||

| 6mm | 1040 | 100 | |||||

| Ho thatafala | > 7H | ||||||

|

| AG fafatsa barbotage | AG Chemical etching | |||||

| Teko ea anti corsion | Khatiso ea NaCL 5%: | N/A | |||||

| Teko ea ho hanyetsa mongobo | 60 ℃, 90% RH, lihora tse 48 | N/A | |||||

| Tlhahlobo ea abrasion | 0000 # boea ba tšepe bo nang le 100ogf, 6000cycles, 40cycles/min | N/A | |||||

Ho sebetsa

Khalase ea anti-glare, e bitsoang khalase ea AG, ke mofuta oa khalase e nang le phekolo e khethehileng holim'a khalase.Molao-motheo ke ho sebetsana le mokhabiso oa boleng bo holimo mahlakoreng a le mong kapa ka bobeli ho etsa hore e be le khanya e tlase ho feta khalase e tloaelehileng, ka hona ho fokotsa ho kena-kenana ha leseli le haufi, ho ntlafatsa ho hlaka ha setšoantšo, ho fokotsa ponahalo ea skrine, le ho etsa hore setšoantšo se hloeke le ho feta. e sebetsang haholoanyane, e lumellang bashebelli ho natefeloa ke litlamorao tse ntle tsa pono.

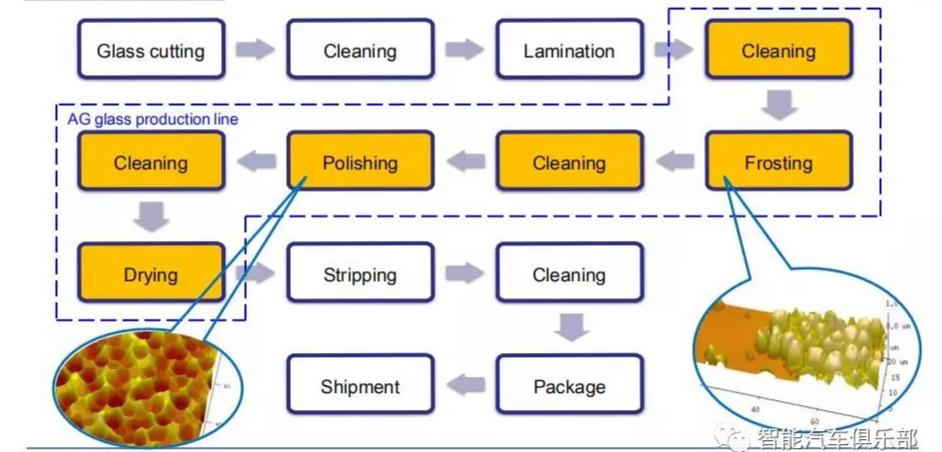

Molao-motheo oa tlhahiso ea khalase ea AG e arotsoe ka AG 'mele oa spray coating le AG chemical etching

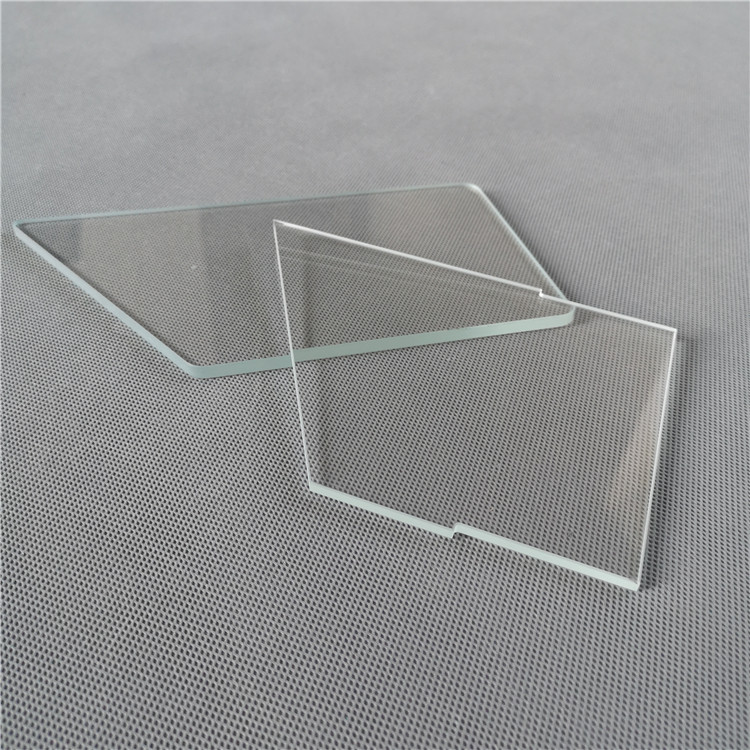

1. AG o fafatsa khalase ea ho roala

Ho bolela hore ka khatello kapa matla a centrifugal, likaroloana tse kang sub-micron silica li koahetsoe ka mokhoa o ts'oanang holim'a khalase ka sethunya sa spray kapa atomizer ea disc, 'me ka mor'a ho futhumatsa le ho phekola, ho thehoa lera la likaroloana holim'a khalase. bokahodimo.Hlakola khanya ea leseli ho fihlela phello e khahlanong le khanya

Ha e ntse e fafatsa holim'a khalase, botenya ba khalase bo tla ba botenya hanyane kamora ho roala.

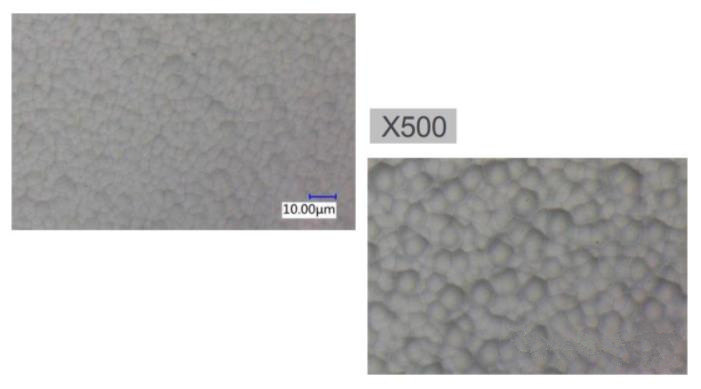

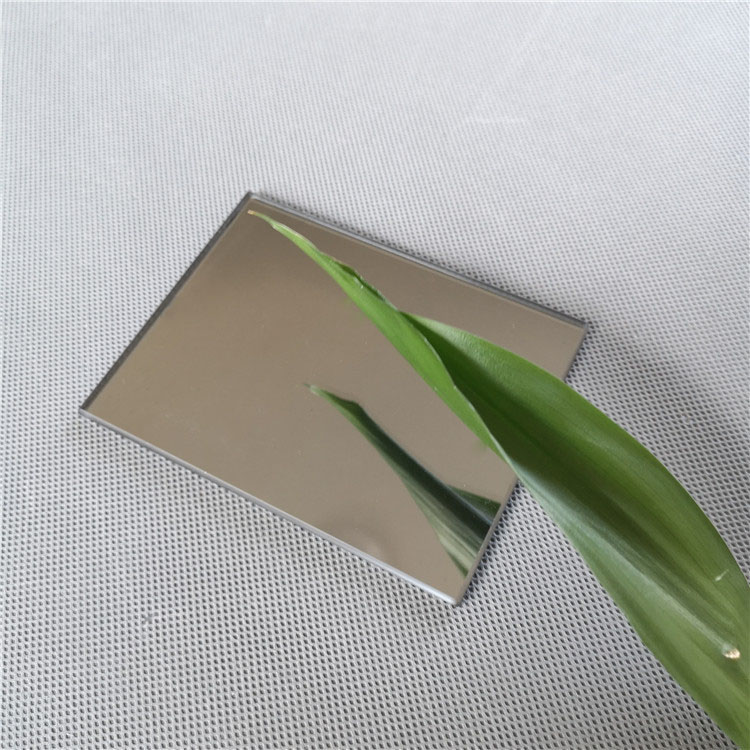

2. AG lik'hemik'hale etching khalase.

E bua ka ts'ebeliso ea lik'hemik'hale.e hloka lik'hemik'hale tse kang hydrofluoric acid, hydrochloric acid, le sulfuric acid ho kenya bokaholimo ba khalase ho tloha ho benyang ho isa ho matt le karoloana ea micron, e leng phello ea ketso e kopaneng ea ionization equilibrium, lik'hemik'hale. karabelo, ho qhibiliha le recrystallization, phetoho ea ion le liketso tse ling.

Ha e ntse e khabisa bokaholimo ba khalase, botenya ba khalase bo tla ba bosesane hanyane ho feta pele.

Bakeng sa sepheo sa ho sireletsa kapa sa EMI, re ka eketsa ITO kapa FTO coating.

Bakeng sa tharollo ea anti glare, re ka sebelisa antiglare coating hammoho ho ntlafatsa taolo ea khanya ea leseli.

Bakeng sa tharollo ea oleophobic, koae ea khatiso ea menoana e ka bamolemo ka ho fetisisaMotsoako oa ho ntlafatsa ho ama le ho etsa hore skrine ea ho ama ho be bonolo ho e hloekisa.

Khalase ea AG(anti glare) VS AR(anti reflective), phapang ke efe, e betere ke efe.bala haholoanyane

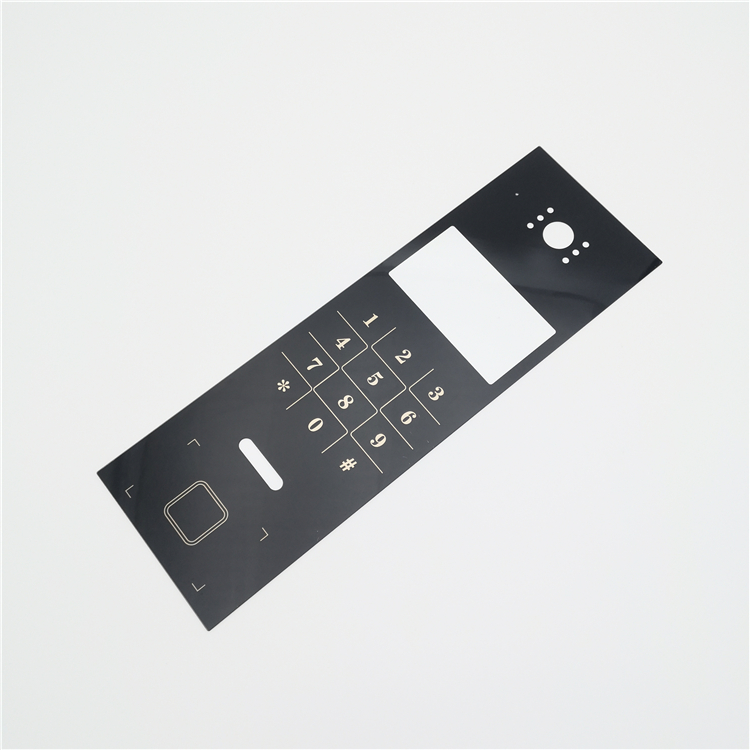

Tšebeliso e amanang

Khalase e hanyetsanang le lik'hemik'hale tse thibelang mahlaseli a kotsi bakeng sa phanele ea ho ama ea indasteri

Khalase e kholo ea boholo bo boholo ba anti glare bakeng sa li-screen signage touch screens

Lense ea sekoaelo sa khalase e sa benyang bakeng sa sekirini sa ho tsamaea sa koloi