white ceramic glass for tea stove

Technical data

|

Silk screen printing glass |

UV printing glass |

||

|

|

organic printing |

ceramic printing |

|

|

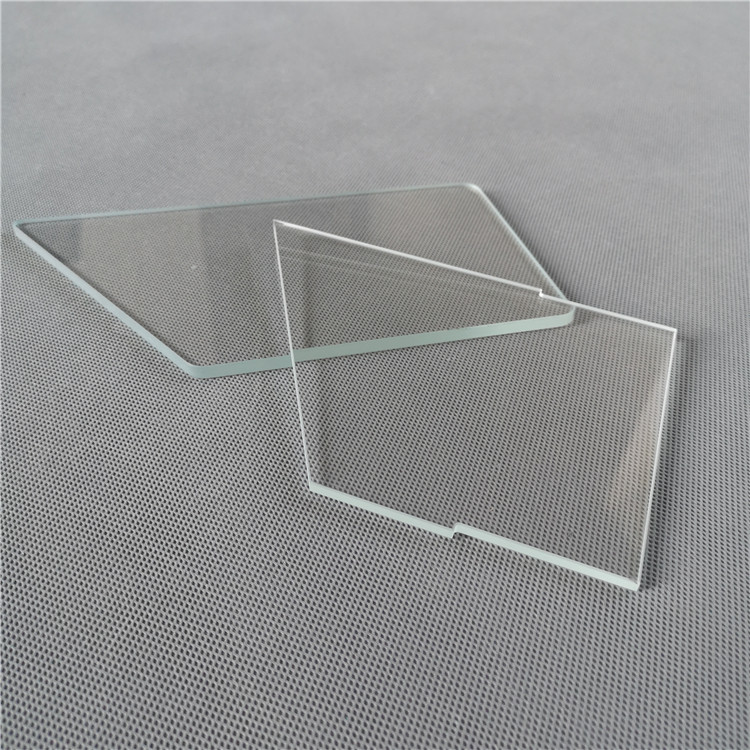

Applicable thickness |

0.4mm-19mm |

3mm-19mm |

no limited |

|

Processing size |

<1200*1880mm |

<1200*1880mm |

<2500*3300mm |

|

Printing tolerance |

±0.05mm min |

±0.05mm min |

±0.05mm min |

|

Features |

heatresistant high gloosy thin ink layer higher quality output variety of ink versatility high flexibility on material's size and shape |

scratch resistant UV resistant heat resistant weather proof chemical resistant |

scratch resistant UV resistant complicated and various color applicable wider variety of printing materials high efficiency on multi-color printing |

|

Limits |

one color layer each time cost higher for small qty |

one color layer each time limited color option cost higher for small qty |

inferior ink adhension cost higher for big qty |

Processing

1: Screen printing, also called silk screen printing,serigraphy,silk printing,or organic stoving

Refers to the use of silk screen as a plate base, and a screen printing plate with graphics and text is made by a photosensitive plate-making method. Screen printing consists of five elements, screen printing plate, squeegee, ink, printing table and substrate.

The basic principle of screen printing is to use the basic principle that the mesh of the graphic part of the screen printing plate is transparent to the ink, and the mesh of the non-graphic part is not permeable to the ink.

2: Processing

When printing, pour ink on one end of the screen printing plate, apply a certain pressure to the ink part of the screen printing plate with a scraper, and move to the other end of the screen printing plate at the same time. The ink is squeezed onto the substrate by the scraper from the mesh of the graphic part during the movement. Due to the viscosity of the ink, the imprint is fixed within a certain range. During the printing process, the squeegee is always in line contact with the screen printing plate and the substrate, and the contact line moves with the movement of the squeegee. A certain gap is maintained between them, so that the screen printing plate during printing generates a reaction force on the squeegee through its own tension. This reaction force is called rebound force. Due to the effect of the resilience, the screen printing plate and the substrate are only in moving line contact, while the other parts of the screen printing plate and the substrate are separated. The ink and the screen are broken, which ensures the printing dimensional accuracy and avoids the smearing of the substrate. When the scraper scrapes the entire layout and lifts up, the screen printing plate is also lifted, and the ink is gently scraped back to the original position. So far it's one printing procedure.

Ceramic printing,also called high-temperature printing,or ceramic stoving

Ceramic printing has same processing theory as normal silk screen printing,what make it different is that ceramic printing finished on glass before tempered (normal screen printing on glass is after tempered),so the ink can be sintered on glass when furnace heat to 600℃ during tempering instead of just simply laying on glass surface,which makes glass has heat resistant,UV resistant,scratch resistant and weather proof characteristic,those make ceramic printing glass is the best choice for outdoor application especially for lighting.

UV digital printing, also known as Ultraviolet Printing.

UV Printing refers to a commercial printing process that uses ultraviolet curing Technology, is a form of digital printing.

The UV Printing process involves special inks that have been formulated to dry quickly when exposed to ultraviolet (UV) light.

As the paper (or other substrate) passes through the printing press and receives wet ink, it is immediately exposed to UV light. Because the UV light dries the application of ink instantly, the ink does not have the opportunity to seep or spread. Hence, images and text print in sharper detail.

When it comes to printed on glass

comparing with UV printing,silk screen glass advantage as follow

1: More shinning and vivid color

2: High production efficiency and cost saving

3: High quality output

4: better ink adhension

5: aging resistant

6: no limits on substrate’s size and shape

This make screen printing glass has wider application than UV printing on many products such as

consumer electronics

industrial touch screens

automotive

medical display,

farm industry

military display

marine monitor

home appliance

home automation device

lighting

Complicate muti-color printing.

Printing on uneven surface.

Silk screen printing only can finish one color at one time, when it come to multi color printing (which is more than 8 color or gradient color) ,or glass surface is not even or with bevel, then UV printing come into play.

Related Cases

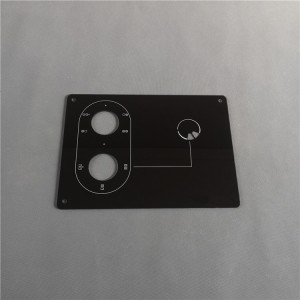

Ceramic Printed Tempered Glass For Induction

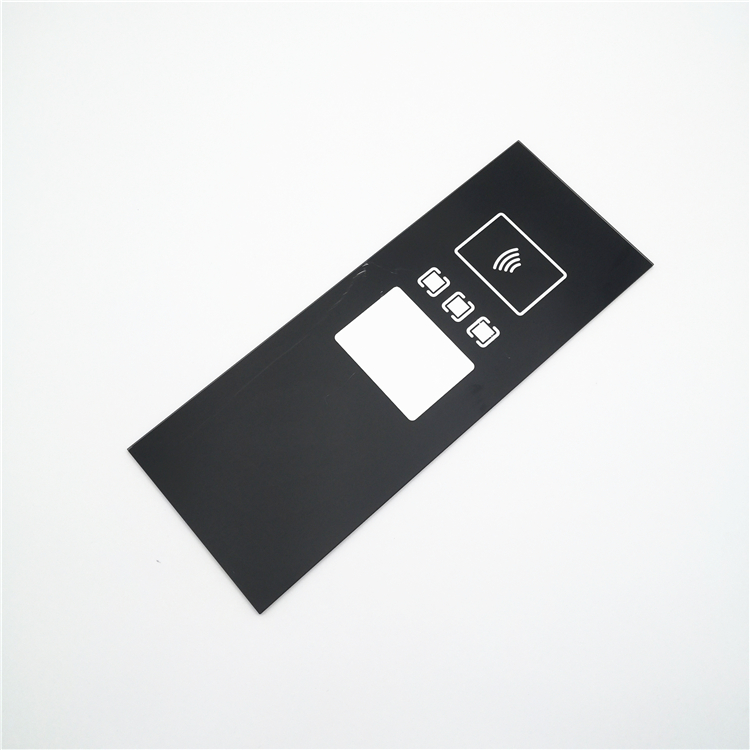

Custom Printed Glass For Smart Door Lock

Silk Screen Tempered Glass For Touch Switch