iglasi epholileyo yeceramic, umboneleli weglasi onganyangekiyo

Idatha yobugcisa

| Iglasi yoshicilelo lwesikrini sesilika | Iglasi yokushicilela ye-UV | ||

|

| ushicilelo lwendalo | ushicilelo lwe-ceramic | |

| Ubukhulu obusebenzayo | 0.4mm-19mm | 3mm-19mm | akukho mda |

| Ubungakanani bokuqhubekekisa | <1200*1880mm | <1200*1880mm | <2500*3300mm |

| Unyamezelo loshicilelo | ±0.05mm min | ±0.05mm min | ±0.05mm min |

| Iimbonakalo | ukumelana nobushushu okuphezulu okukhazimlayo kwe-inki ebhityileyo umaleko ophezulu umgangatho wemveliso eyahlukeneyo ye-inki eguquguqukayo ephezulu kubungakanani bemathiriyeli kunye nokumila | Ukumelana nemikrwelo ye-UV ekwaziyo ukumelana nobushushu kubungqina bemozulu | I-UV ekwazi ukumelana nemikrwelo entsonkothileyo kunye nemibala eyahlukeneyo esebenzayo ebanzi ebanzi yemathiriyeli yoshicilelo oluphezulu kushicilelo olunemibala emininzi. |

| Imida | Umaleko omnye wombala ngexesha ngalinye ixabiso eliphezulu kwi-qty encinci | Umaleko omnye wombala ngexesha ngalinye ukhetho lombala olulinganiselweyo lubiza phezulu kwi-qty encinci | Ukongezwa kwe-inki engaphantsi kunexabiso eliphezulu kwi-qty enkulu |

Iyaqhuba

1: Ukuprintwa kwesikrini, okukwabizwa ngokuba yisilika yoshicilelo lwesikrini, i-serigraphy, ushicilelo lwesilika, okanye isitovu sendalo

Ibhekisa kusetyenziso lwesikrini sesilika njengesiseko sepleyiti, kwaye ipleyiti yoshicilelo yesikrini enemizobo kunye nombhalo wenziwa yindlela yokwenza i-photosensitive plate-making.Ushicilelo lwesikrini lunezinto ezintlanu, ipleyiti yoshicilelo lwesikrini, i-squeegee, i-inki, itafile yoshicilelo kunye ne-substrate.

Umgaqo osisiseko woshicilelo lwekhusi kukusebenzisa umgaqo osisiseko wokuba umnatha wenxalenye yomzobo wepleyiti yoshicilelo lwesikrini ubonakala ngokucacileyo kwi-inki, kwaye umnatha wenxalenye engeyiyo umzobo awungeneki kwi-inki.

2: Ukusetyenzwa

Xa ushicilela, galela i-inki kwelinye icala lepleyiti yoshicilelo lwesikrini, faka uxinzelelo oluthile kwindawo ye-inki yepleyiti yokushicilela isikrini kunye ne-scraper, kwaye uye kwelinye icala lepleyiti yokushicilela isikrini kwangaxeshanye.I-inki icinezelwe kwi-substrate yi-scraper evela kwi-mesh yecandelo lomzobo ngexesha lokuhamba.Ngenxa ye-viscosity ye-inki, i-imprint igxininiswe ngaphakathi koluhlu oluthile.Ngethuba lenkqubo yokushicilela, i-squeegee isoloko ihambelana nomgca wokuprinta kwesikrini kunye ne-substrate, kwaye umgca woqhagamshelwano uhamba kunye nokuhamba kwe-squeegee.Umsantsa othile uyagcinwa phakathi kwabo, ukuze ipleyiti yoshicilelo lwesikrini ngexesha loshicilelo ivelise amandla okusabela kwi-squeegee ngoxinzelelo lwawo.La mandla okusabela abizwa ngokuba yi-rebound force.Ngenxa yempembelelo yokuqina, ipleyiti yokushicilela isikrini kunye ne-substrate kuphela ekunxibelelaneni komgca ohambayo, ngelixa ezinye iinxalenye zeplate yokushicilela isikrini kunye ne-substrate ziyahlukana.I-inki kunye nekhusi zaphukile, eziqinisekisa ukuchaneka kobukhulu bokushicilela kwaye kunqande ukuthanjiswa kwe-substrate.Xa i-scraper ikhuhla yonke i-layout kwaye iphakamisa phezulu, ipleyiti yokushicilela isikrini nayo iphakanyisiwe, kwaye i-inki ikhutshiwe ngobumnene ibuyele kwindawo yokuqala.Ukuza kuthi ga ngoku yinkqubo enye yoshicilelo.

Ushicilelo lweCeramic, olukwabizwa ngokuba kushicilelo lobushushu obuphezulu, okanye isitovu seceramic

Ushicilelo lweCeramic lunethiyori efanayo yokusetyenzwa njengesiqhelo soshicilelo lwesikrini sesilika, into eyenza ukuba yahluke kukuba ukuprintwa kwe-ceramic kugqitywe kwiglasi ngaphambi kobushushu (ukuprintwa okuqhelekileyo kwesikrini kwiglasi kusemva kobushushu), ukuze i-inki ifakwe kwiglasi xa ubushushu bomlilo bufikelele kwi-600 ℃ ngexesha lobushushu endaweni yokungqengqa nje kumphezulu weglasi, eyenza iglasi inganyangeki bubushushu, ikwazi ukumelana ne-UV, ixhathise umkrwelo kunye neempawu zobungqina bemozulu, ezo zenza iglasi yoshicilelo lweceramic lolona khetho lulungileyo kwisicelo sangaphandle ngakumbi sokukhanyisa.

Ushicilelo lwedijithali lwe-UV, olukwabizwa ngokuba yi-Ultraviolet Printing.

Ukuprintwa kwe-UV kubhekiselele kwinkqubo yoshicilelo yorhwebo esebenzisa i-ultraviolet yokunyanga iTekhnoloji, luhlobo loshicilelo lwedijithali.

Inkqubo yoShicilelo ye-UV ibandakanya ii-inki ezikhethekileyo ezenzelwe ukuba zome ngokukhawuleza xa zibekwe kukukhanya kwe-ultraviolet (UV).

Njengoko iphepha (okanye enye i-substrate) idlula kumatshini wokushicilela kwaye ifumana i-inki emanzi, ngokukhawuleza ibonakaliswe kukukhanya kwe-UV.Ngenxa yokuba isibane se-UV somisa ukusetyenziswa kwe-inki ngoko nangoko, i-inki ayinalo ithuba lokubona okanye lokusasaza.Ke, imifanekiso kunye nokuprintwa okubhaliweyo ngokweenkcukacha ezibukhali.

Xa kuziwa ekuprintweni kwiglasi

kuthelekiswa noshicilelo lwe-UV, inzuzo yeglasi yeglasi yesilika ngokulandelayo

1: Umbala oqaqambileyo kunye ocacileyo

2: Ukusebenza kakuhle kwemveliso kunye nokonga iindleko

3: Umgangatho ophezulu wemveliso

4: ngcono inki adhension

5: ukuguga ukumelana

6: akukho mida kubungakanani kunye nokumila kwesubstrate

Oku kwenza iglasi yoshicilelo lwesikrini inesicelo esibanzi kunoshicilelo lwe-UV kwiimveliso ezininzi ezinje

i-elektroniki yabathengi

izikrini zokuthintela ishishini

iimoto

umboniso wezonyango,

ishishini lasefama

umboniso womkhosi

imonitha yaselwandle

isixhobo sasekhaya

isixhobo esizisebenzelayo sasekhaya

ukukhanya

Ushicilelo oluntsonkothileyo lwemuti-umbala.

Ushicilelo kumphezulu ongalinganiyo.

Ukuprintwa kwesikrini sesilika kunokugqiba umbala omnye ngexesha elinye, xa kufikwa kushicilelo lwemibala emininzi (ongaphezulu kombala osi-8 okanye umbala wegradient), okanye umphezulu weglasi awukho nokuba nebevel, emva koko ushicilelo lwe-UV lungene.

Amatyala anxulumeneyo

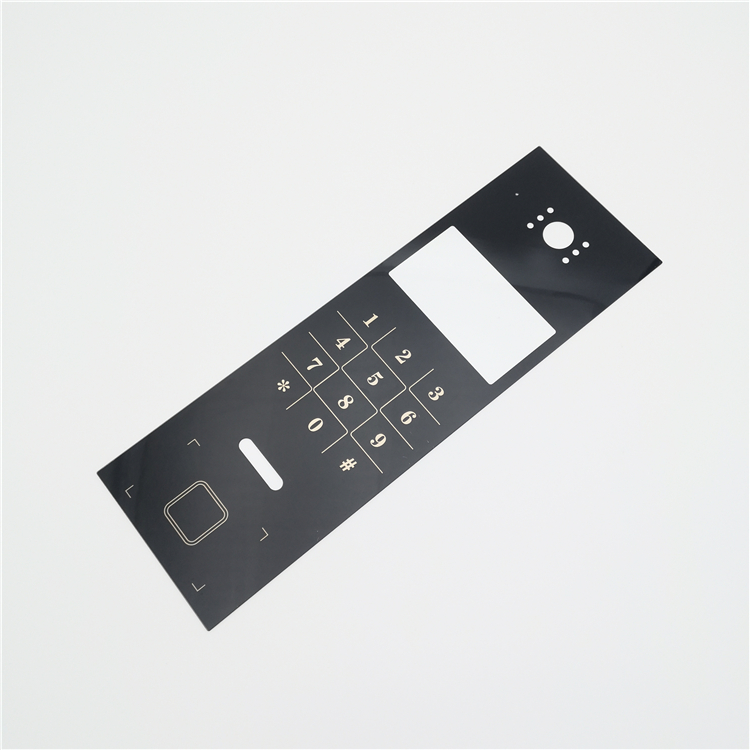

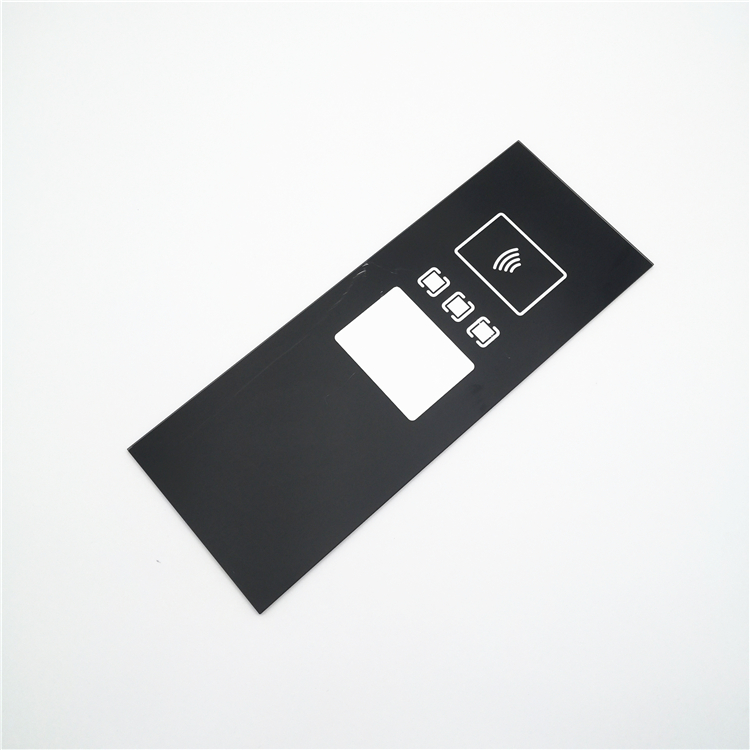

Iglasi eprintiweyo ngokweSiko yeSmart Door Lock

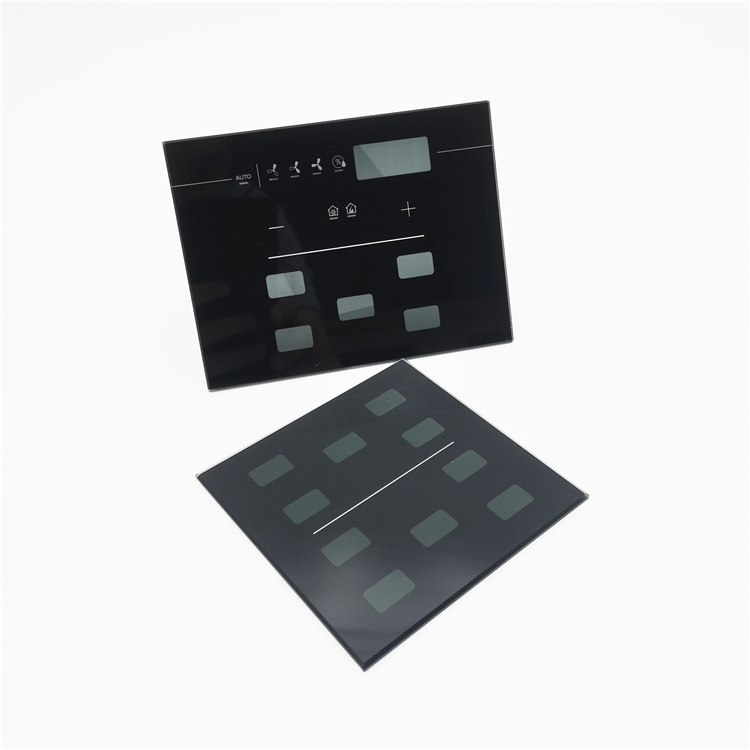

I-Ceramic Printed Tempered Glass yePaneli yoLawulo lokungeniswa

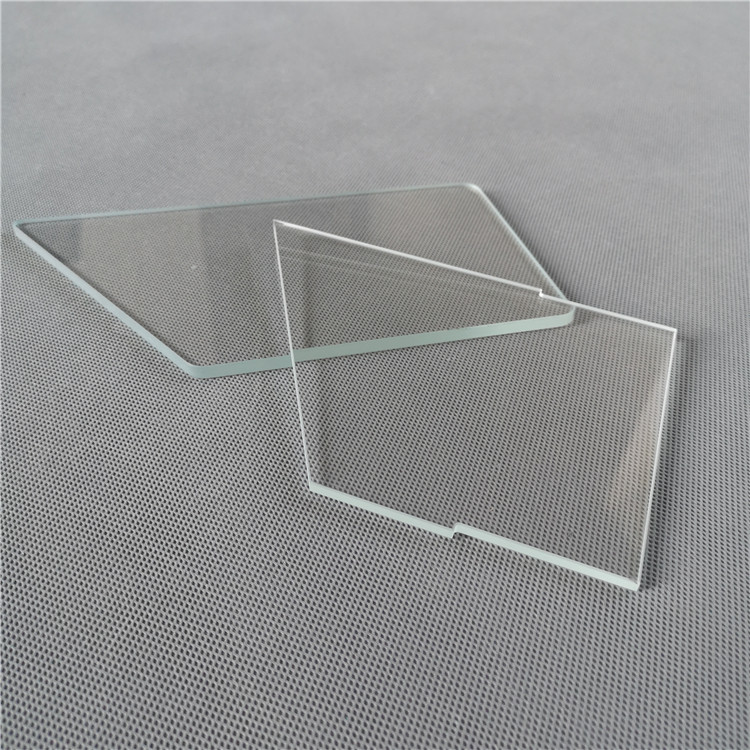

Silk Screen Ubushushu beglasi yeTouch switch