amaslayidi engilazi enziwe ngokwezifiso

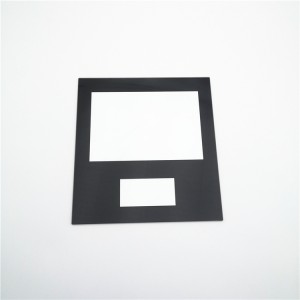

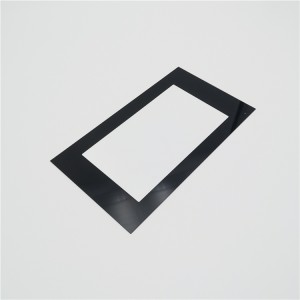

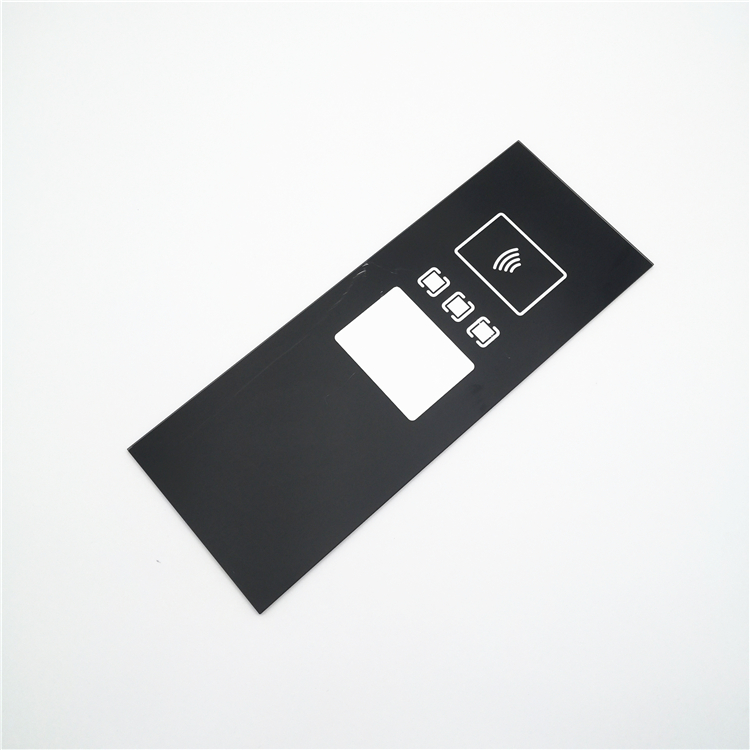

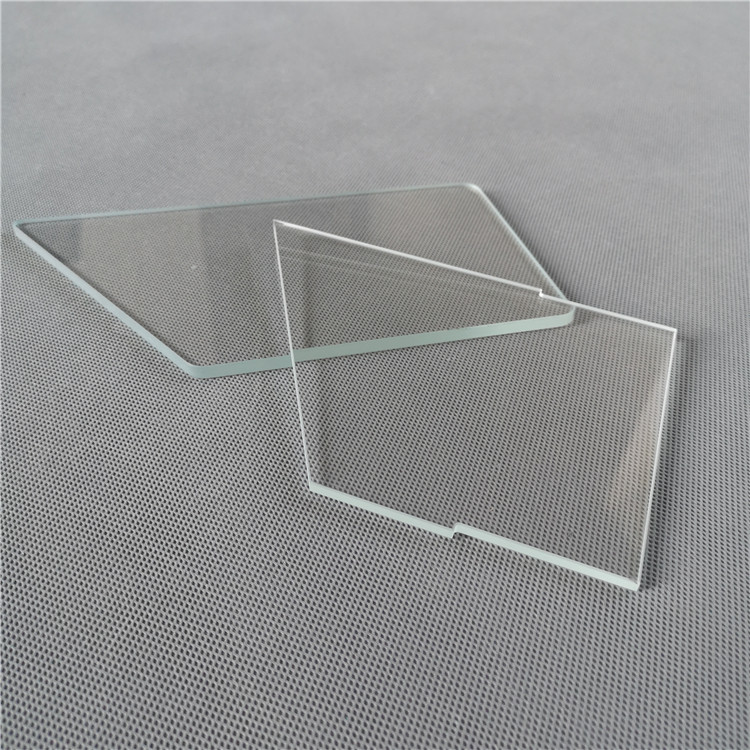

Imikhiqizo Izithombe

I-ITO conductive glass coated yenziwe ngokusabalalisa i-silicon dioxide (SiO2) kanye ne-indium tin oxide (evame ukwaziwa ngokuthi i-ITO) ngobuchwepheshe be-magnetron sputtering ku-substrate yengilazi ngaphansi kwesimo esingenalutho ngokuphelele, okwenza ubuso obumboziwe buthandeke, i-ITO iyinhlanganisela yensimbi enokukhanya okuhle futhi izakhiwo conductive.

Idatha yobuchwepheshe

| Ubukhulu bengilazi ye-ITO | 0.4mm, 0.5mm, 0.55mm, 0.7mm, 1mm, 1.1mm, 2mm, 3mm, 4mm | ||||||||

| ukumelana | 3-5Ω | 7-10Ω | 12-18Ω | 20-30Ω | 30-50Ω | 50-80Ω | 60-120Ω | 100-200Ω | 200-500Ω |

| ukujiya enamathela | 2000-2200Å | 1600-1700Å | 1200-1300Å | 650-750Å | 350-450Å | 200-300Å | 150-250Å | 100-150Å | 30-100Å |

| Ukumelana nengilazi | |||

| Uhlobo lokumelana | ukumelana okuphansi | ukumelana okuvamile | ukumelana okuphezulu |

| Incazelo | <60Ω | 60-150Ω | 150-500Ω |

| Isicelo | Ingilazi yokumelana okuphezulu ngokuvamile isetshenziselwa ukuvikelwa kwe-electrostatic kanye nokukhiqizwa kwesikrini sokuthinta | Ingilazi ejwayelekile yokumelana imvamisa isetshenziselwa ukubonisa ikristalu yohlobo lwe-TN kanye ne-electronic anti-interference(EMI shielding) | Ingilazi yokumelana okuphansi ivame ukusetshenziswa kuma-STN liquid crystal display kanye namabhodi wesekethe asobala |

| Ukuhlolwa okusebenzayo nokuhlolwa kokwethembeka | |

| Ukubekezelelana | ±0.2mm |

| I-Warpage | ukujiya<0.55mm, i-warpage≤0.15% ukujiya>0.7mm,warpage≤0.15% |

| I-ZT imile | ≤1° |

| Ukuqina | > 7H |

| Ukuhlolwa kwe-Coating Abrasion | 0000# uboya bensimbi obuno-1000gf,6000cycles,40cycles/min |

| I-Anti Corrsion Test (ukuhlolwa kwesifutho sikasawoti) | Ukugxila kwe-NaCL 5%:Izinga lokushisa: 35°CIsikhathi sokuhlola: 5min ukumelana noshintsho≤10% |

| Ukuhlolwa kokumelana nokuswakama | 60℃,90%RH,48 amahora ukumelana ukushintsha≤10% |

| Ukuhlolwa kokumelana ne-Acid | Ukugxiliswa kwe-HCL: 6%, Izinga lokushisa: 35°CIsikhathi sokuhlola: 5min ukumelana noshintsho≤10% |

| Ukuhlolwa kokumelana ne-alkali | Ukugxila kwe-NaOH:10%,Izinga lokushisa: 60°CIsikhathi sokuhlola: 5min ukumelana noshintsho≤10% |

| Ukuzinza kwe-Themal | Izinga lokushisa:300°Cisikhathi sokushisa: 30min ukumelana ushintsho≤300% |

Iyacubungula

Isendlalelo se-Si02:

(1) Indima yesendlalelo se-SiO2:

Inhloso enkulu ukuvimbela ama-ion ensimbi ku-soda-calcium substrate ukuthi angasabalalisi kungqimba lwe-ITO.Ithinta ukuqhutshwa kwesendlalelo se-ITO.

(2) Ugqinsi lwefilimu longqimba lwe-SiO2:

Ugqinsi lwefilimu olujwayelekile luvamise ukuba ngu-250 ± 50 Å

(3) Ezinye izingxenye kusendlalelo se-SiO2:

Ngokuvamile, ukuze kuthuthukiswe ukudluliswa kwengilazi ye-ITO, ingxenye ethile ye-SiN4 ifakwa ku-SiO2.

| UKUMELANA KWEGLASI | ||||||

| UHLOBO | ukumelana okuphansi | ukumelana okuvamile | ukumelana okuphezulu | |||

| Incazelo | <60Ω | 60-150Ω | 150-500Ω | |||

| Isicelo | Ingilazi yokumelana okuphezulu ngokuvamile isetshenziselwa ukuvikelwa kwe-electrostatic kanye nokukhiqizwa kwesikrini sokuthinta | Ingilazi ejwayelekile yokumelana imvamisa isetshenziselwa ukubonisa ikristalu yohlobo lwe-TN kanye ne-electronic anti-interference(EMI shielding) | Ingilazi yokumelana okuphansi ivame ukusetshenziswa kuma-STN liquid crystal display kanye namabhodi wesekethe asobala | |||

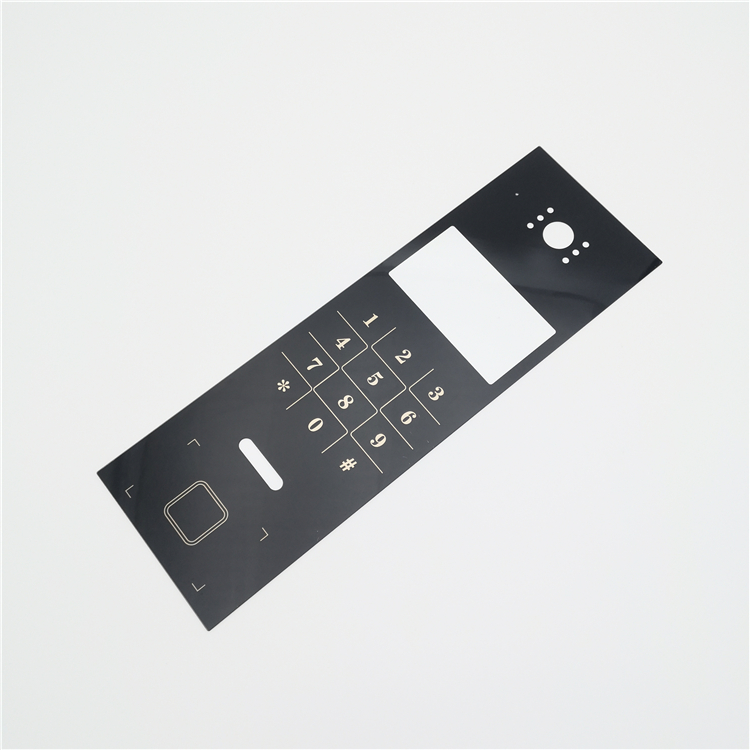

Uhlelo lokusebenza oluhlobene

I-Ito Glass Yokubonisa Kwezempi Emi Shielding

I-Ito Coated Glass Yephaneli ye-Hmi Touch

Ingilazi eqinile ye-Ito Conductive Yesikali Somzimba